Products

- STAMPINGMASTERS ENTERPRISE CO., LTD.

- Products

- Seal Washers

- Seal Washers(Standard type Ⅰ)

- CBB-Hex Socket Head Cap Screws(dyed black)

- CAP-CBB-Hex Socket Head Cap Screws(Materials:SCM435+Blackened/Box)

- SCBB ASCBB-Hex Socket Head Cap Screws(Materials:SUS304)

- CAP-SCBB-Hex Socket Head Cap Screws(Materials:SUS304\BOX)

- EBS EBSH EBSST-Space Saving Bolts(Materials:S45C/SCM435/SUS304)

- EBSS EBSM EBSTS-Space Saving Bolts(Materials:SCM435/SUS304)

- SMA222 SMA223 SMA224-Space Saving Torx screw(Materials:Steel/SUS304)

- RCBB RSCBB-Hex Head Bolt(Materials:SCM435/SUS304)

- BCBB SBCBB-Half round head socket head cap screw(Materials:SCM435/SUS304)

- TKJ MKJ-Half round head socket head cap screw(Materials:Steel/SUS)

- FBB SFBB-Countersunk head hexagon socket head screw (Material: SCM435 / SUS)

- TFBJ PFBJ-Countersunk head Phillips screw (Material: Steel/SUS)

- SGR912.2-Hexagon socket head cap screws (with anti-dropping design) (Material: SUS304)

- BBRSS BRSS-Round head Phillips screw (Material: Steel/SUS)

- NSARA NSARAS-Countersunk head Phillips screw (Material: Steel/SUS)

- BSARA BSARAS-Low Countersunk head Phillips screw (Material: Steel/SUS)

- TDJ TDJS-Round Head Phillips Screws (Material:Steel/SUS)

- B722-Hexagon Bolts (Material: Steel)

- Y012-Hexagon Bolts (Material: Steel)

- B22-Hexagon Bolts (Material: Steel)(Full teeth)

- B23-Hexagon Bolts (Material: Steel)(Full teeth)

- B22-Hexagon Bolts (Material: Steel)(Half teeth)

- B23-Hexagon Bolts (Material: Steel)(Half teeth)

- Y111-Hexagon bolt (Material: SCM435)

- Y306-Hexagon Phillips Bolts (Material: Steel)

- Y303-Hexagon Phillips Bolts (Material: SUS)

- B730-Hexagon socket head screw (Material: SCM435)(Full teeth)

- Y154-Hexagon socket head screw (Material: steel)(Full teeth)

- B30-Hexagon socket head screw (Material: SCM435)(Full teeth)

- B44-Hexagon socket head screw (Material: SUS304)(Full teeth)

- B730-Hexagon socket head screw (Material: SCM435)(Half teeth)

- B62-Hexagon socket head screw (Material: SCM435)

- Y154-Hexagon socket head screw (Material: steel)(Half teeth)

- B30-Hexagon socket head screw (Material: SCM435)(Half teeth)

- B44-Hexagon socket head screw (Material: SUS304)(Half teeth)

- B081-Hexagon socket head cap screws (Material: steel)(Full teeth)

- B089-Hexagon socket head cap screws (Material: SUS304)

- B774-Hexagon socket head cap screws (Material: SCM435)

- B773-Countersunk head socket head cap screws (Material: SCM435)

- B73-Countersunk head socket head cap screws (Material: SCM435)(Full teeth)

- B73-Countersunk head socket head cap screws (Material: SCM435)(Half teeth)

- B081-Low head hexagon socket head screw (Material: Steel)(Half teeth)

- Y311-Super low head hexagon socket head screw (Material: SUS304)

- Y013-Hexagon socket head cap screws (anti-loosening) (Material: SCM435)

- WGWA QCMT SCFT SSPT-Hex Socket Head Cap Screws(Materials:PC/RENY/PEEK/PPS))

- QCMP SCFPB SSPP PICB-Hex Socket Head Cap Screws(Materials:RENY/PEEK/PPS/PI)

- QCMC SCFC SSPC-Space Saving Torx screw(Materials:RENY/PEEK/PPS)

- RSCBP PEEKBT PPSBT-Hex Head Bolt(Materials:PA/PEEK/PPS)

- SRAB SCFP SSPW-Half round head cross plastic screw (Material: RENY/PEEK/PPS)

- PEEKFH PPSFH-Countersunk head cross plastic screw (Material: PEEK/PPS)

- CBP-Hexagon socket head plastic screw (Material: PC)

- PCPH-Half round head cross plastic screw (Material: PC)

- PCFH-Countersunk head cross plastic screw (Material: PC)

- PCOH-Round Countersunk Head Cross Plastic Screws (Material: PC)

- PCBT-Hexagon plastic bolts (Material: PC)

- PPSLH-Star Plastic Screw (Material: PP)

- RENYBKPH-Half round head cross plastic screw (Material: RENY)

- RENYFH-Countersunk head cross plastic screw (Material: RENY)

- RENYBT-Hexagon plastic bolts (material: RENY)

- RENYTPH-Half round head cross plastic screw (Material: RENY)

- RENYMPH-Super low dome head Phillips plastic screw (material: RENY)

- RENYSMCH-Super low head cross plastic screw (material: RENY)

- RENYLMCH-Super low head cross plastic screw (material: RENY)

- PEEK-BT-Outer Hexagon Slotted Plastic Bolts (Material: PEEK)

- PEEKLH-Torx Plastic Screw (Material: PEEK)

- PEEKMPH-Super low dome head Phillips plastic screw (material: PEEK)

- PEEKSMCH-Super low head cross plastic screw (Material: PEEK)

- PEEKLMCH-Super low head cross plastic screw (material: PEEK)

- PEEKPH-Half round head cross plastic screw (material: PEEK)

- PEEK-PH-Super low head plastic screw (Material: PEEK)

- PEEK-FH-Countersunk head slotted plastic screw (Material: PEEK)

- PEEKCB-Hexagon socket head plastic screw (Material: PEEK)

- PVDFPH-Half round head cross plastic screw (Material: PVDF)

- PVDFFH-Countersunk head cross plastic screw (Material: PVDF)

- PVDFBT-Hexagon plastic bolts (Material: PVDF)

- PVDFCB-Hexagon socket head plastic screw (material: PVDF)

- PFACB-Hexagon socket head plastic screw (Material: PFA)

- PFA-BT-Hexagon socket head bolt (Material: PFA)

- PFA-HH-Slotted Plastic Screws (Material: PFA)

- PTFEBT-Hexagon plastic bolts (Material: PTFE)

- PVCBT-External Hexagon Plastic Bolts (Material: PVC)

- PVCCB-Hexagon socket head plastic screw (Material: PVC)

- PPBT-Hexagon plastic bolts (Material: PP)

- FH-Countersunk head cross plastic screw (Material: PEEK)

- PH-Half round head cross plastic screw (Material: PEEK)

- BPC-BTM-Hexagon plastic bolts (Material: PC)

- BPPS-BTM-Hexagon plastic bolts (Material: PPS)

- BRENY-BTM-Hexagon plastic bolts (Material: RENY)

- BPEEK-BTM-External Hexagon Plastic Bolts (Material: PEEK)

- BPVC-BTM-External Hexagon Plastic Bolts (Material: PVC)

- BPC-CBM-Hexagon socket head plastic screw (Material: PC)

- BPPS-CBM-Hexagon socket head plastic screw (Material: PPS)

- BRENY-BKCBM-Hexagon socket head plastic screw (Material: RENY)

- BPEEK-CBM-Hexagon socket head plastic screw (Material: PEEK)

- BPVC-CBM-Hexagon socket head plastic screw (Material: PVC)

- BRENY-BKLCM-Low head hexagon socket head plastic screw (Material: RENY)

- BPEEK-LCM-Low head hexagon socket head plastic screw (Material: PEEK)

- PEEKFH-Countersunk head cross plastic screw (material: PEEK)

- PEEKHB-External Hexagon Plastic Bolts (Material: PEEK)

- PEEKPH-Half round head cross plastic screw (Material: PEEK)

- PEEKSCK-Hexagon socket head plastic screw (Material: PEEK)

- PEEKSC-Hexagon socket head plastic screw (Material: PEEK)

- PEEKSH-Outer Hexagon Slotted Bolt (Material: PEEK)

- SCBPEKM-Hexagon socket head plastic screw (Material: PEEK)

- SCBFPEKM-Hexagon socket head plastic screw (Material: PEEK)

- SBTPEKM-External Hexagon Plastic Bolts (Material: PEEK)

- SBTEPEKM-Outer Hexagon Slotted Bolt (Material: PEEK)

- SBTPEKM-External Hexagon Plastic Bolts (Material: PEEK)

- SCBFPEKM-Hexagon socket head plastic screw (Material: PEEK)

- SCBPEKM-Hexagon socket head plastic screw (Material: PEEK)

- SFHPEKM-Countersunk head cross plastic screw (Material: PEEK)

- SPHPEKM-Half round head cross plastic screw (Material: PEEK)

- B768 B68-Combination screw (external hexagon cross bolt)

- B716-Combination screws (external hexagon bolts)

- Y336-Combination screws (external hexagon Phillips bolts)

- Y103-Combination screws (external hexagon bolts)

- B078-Combination screws (hexagon socket head screws)

- B877 B777-Combination screws (hexagon socket head screws)

- Y15S-Combination screws (hexagon socket head screws)

- ANEE SANEE-Fully-Threaded Bolts(Material: SS41/SUS304)

- SPPA SPPE SPPO SPPS-Fully-Threaded Bolts(Material: PA/PEEK/POM/PPS)

- SGR551.1-Fully-Threaded Bolts With slotted hole (Material: Steel)

- PCLB-Plastic Fully-Threaded Bolts(Material:PC)

- PCZB-Plastic Fully-Threaded Bolts (Material: PC)

- RENYZB-Plastic Fully-Threaded Bolts (Material: RENY)

- TR-Die spring (JIS standard. Compression 50%)

- TY-Die spring (JIS standard. Compression 50%)

- TF-Die spring (JIS standard. Compression 50%)

- TL TLR-Die spring (JIS standard. Compression 40%)

- TM-Die spring (JIS standard. Compression 32%)

- TH-Die spring (JIS standard. Compression 24%)

- TB-Die spring (JIS standard. Compression 20%)

- TJL-Die spring (ISO specification. Compression 40%)

- TJM-Die spring (ISO specification. Compression 37.5%)

- TJH-Die spring (ISO specification. Compression 30%)

- TJB-Die spring (ISO specification. Compression 25%)

- TU-Die spring (JIS standard. Compression 65%)

- LR-Round Wire Spring (Material: SWOSC-V, Compression 32%)

- LR MR-Round Wire Spring (Material: SWOSC-V, Compression 24%)

- LR-Round Wire Spring (Material: SWOSC-V, Compression 24%)(fixed length: 1 meter)

- AY-Round Wire Spring (Material: SWP, Compression 75%)

- AR-Round Wire Spring (Material: SWP, Compression 60%)

- AF-Round Wire Spring (Material: SWP, Compression 45%)

- AL-Round Wire Spring (Material: SWP, Compression 40%)

- AT-Round Wire Spring (Material: SWP, Compression 40%)

- AM-Round Wire Spring (Material: SWP, Compression 35%)

- AH-Round Wire Spring (Material: SWP, Compression 30%)

- AB-Round wire spring (Material: SWP, compression 25%)

- NAL NAM-Round Wire Spring (Material: SWP, Compression 32%/40%)

- OV-Round wire spring (Material: SUS304, compression 70%)

- OY-Round wire spring (material: SUS304, compression 75%)

- OR-Round wire spring (material: SUS304, compression 60%)

- OF-Round wire spring (Material: SUS304, compression 45%)

- OL-Round wire spring (Material: SUS304, compression 40%)

- OT-Round wire spring (material: SUS304, compression 40%)

- OM-Round wire spring (Material: SUS304, compression 35%)

- OH-Round wire spring (Material: SUS304, compression 30%)

- OB-Round wire spring (Material: SUS304, compression 25%)

- TCM-Countertop wave spring (wave end type) (Material: Spring steel)

- TCM-Countertop wave spring (wave end type) (material: stainless steel)

- TCMS-On top wave spring (flat end type) (Material: Spring steel)

- TCMS-Countertop Wave Spring (Flat End Type) (Material: Stainless Steel)

- TSSB-Wave Spring (Interface Type) (Material: Spring Steel)

- TSSB-Wave Spring (Interface Type) (Material: Stainless Steel)

- TSSB-Wave Spring (Notch Type) (Material: Spring Steel)

- TSSB-Wave Spring (Notch Type) (Material: Stainless Steel)

- AG-Gas spring (ISO standard (initial load 250kgf))

- AG-Gas spring (ISO standard (initial load 500kgf))

- AG-Gas spring (ISO standard (initial load 750kgf))

- AG-Gas spring (ISO standard (initial load 1500kgf))

- AG-Gas spring (ISO standard (initial load 3000kgf))

- AG-Gas spring (ISO standard (initial load 5000kgf))

- AG-Gas spring (ISO standard (initial load 7500kgf))

- AG-Gas spring (ISO standard (initial load 10000kgf))

- CW-Gas spring (compact height type (initial load 170kgf))

- CW-Gas spring (compact height type (initial load 320kgf))

- CW-Gas spring (compact height type (initial load 350kgf))

- CW-Gas spring (compact height type (initial load 500kgf))

- CW-Gas spring (compact height type (initial load 750kgf))

- CW-Gas spring (compact height type (initial load 1000kgf))

- CW-Gas spring (compact height type (initial load 1500kgf))

- CW-Gas spring (compact height type (initial load 2400kgf))

- CW-Gas spring (compact height type (initial load 4200kgf))

- CW-Gas spring (compact height type (initial load 6600kgf))

- CW-Gas spring (compact height type (initial load 9500kgf))

- CW-Gas spring (compact height type (initial load 11800kgf))

- CW-(Copy)-Gas spring (compact height type (initial load 11800kgf))

- WC WM WS-Washer (Material: S45C/SUS304)

- TT RR-Die washer (Material: S45C)

- PW 5591-Die washer (material: S45C/copper)

- PAW PBW PCW-Die washer (Material: SK3)

- 23060-Fixture Washer (Material: Steel / SUS303)

- 23060-Washer (Material: Steel)

- EPA-Bearing washer (Material: S45C / SUS304)

- EPB-Bearing washer (Material: S45C / SUS304)

- EPC-Bearing washer (Material: S45C / SUS304)

- 5501 5503-Washer (Material: Steel / Stainless Steel)

- MSRBB LRBB-Die washer (Material: SK5)

- CIMSR-Thin washer (material: stainless steel)

- LTPN-Automotive mold gasket (material: SUS304)

- LBSNP D-DIP-A-Automotive mold gasket (material: stainless steel)

- BRB BRF-Bearing washer

- FRS.A FRS.S FRB.B FRC.C FRA.A-Bearing spacer (custom size)

- RS RB-Laminated bearing washers

- FRLS FRLB FRLA-Laminated bearing spacer (customized size)

- FFS.A FFS.S FFB.B FFC.C FFA.A-Reducer gasket (custom size)

- FKS.A FKS.S FKB.B FKC.C FKA.A-Keyway washer (custom size)

- FCS.A FCS.S FCB.B FCC.C FCA.A-Die gasket (custom size)

- D-DIP-C-Automotive mold gasket (material: stainless steel)

- PLTP-Automotive mold gasket (material: SUS304)

- LBSFP-Automotive mold gasket (material: SUS304)

- D-DIP-G-Automotive mold gasket (material: stainless steel)

- D-DIP-B-Automotive mold gasket (material: SUS304)

- SMPP-Automotive mold gasket (material: SUS304)

- MSSA MSSB-paraller pin(Material: SUJ2)

- NP-paraller pin(Material: SUJ2)

- WPW NPV-paraller pin(Material: SUJ2)

- MSSE MSSF-paraller pin(Material: SUS420)

- MSSC MSSD MSSG MSSH-paraller pin(Material: SUS)

- NPBG NPBGP-paraller pin(Material: Steel, SUS)(Single side thread)

- NPBN NPBNP NPB-paraller pin(Material: Steel, SUS)(Single side thread)

- NPBS NPBSE-paraller pin(Material: Steel, SUS)(Single side thread)

- NPKA NPKAN-paraller pin(Material: SUJ2)

- TP-taper pin(Material: SUJ2)(Taper: 1/50)

- ITP-taper pin(Material: SUJ2)(Taper: 1/50)(Single side thread)

- OTP-taper pin(Material: SUJ2)(Taper: 1/50)

- ATP-taper pin(Material: SUJ2)(Taper: 1/48)(imperial unit)

- 22630-dowel pin(Material: SUJ2)(spherical)

- 22630-dowel pin(Material: steel)(Flat, Cone)

- 22630.1~22630.4-dowel pin(Material: steel 、 SUS)(Flat)

- 22630.15~22630.18-dowel pin(Material: steel 、 SUS)(Flat)

- 22630-dowel pin(Material: steel)(tapered surface)

- 22630.35~22630.37-dowel pin(Material: steel 、 SUS)(tapered surface)

- 22630.23~22630.26-dowel pin(Material: steel 、 SUS)(tapered surface)

- 22630.52~22630.57-dowel pin(Material: steel、SUS)(R type)

- 22630.5~22630.8-dowel pin(Material: steel 、 SUS)(Flat)

- 22630.11~22630.14-dowel pin(Material: steel 、 SUS)(Flat)

- 22630.19-dowel pin(Material: steel 、 SUS)(Flat)

- 22630.20~22630.22-dowel pin(Material: steel 、 SUS)(Flat)

- 22630.38~22630.41-dowel pin(Material: steel 、 SUS)(tapered surface)

- 22630.42 22630.43 22630.58-dowel pin(Material: steel 、 SUS)(tapered surface)

- 22630.27~22630.30-dowel pin(Material: steel 、 SUS)(tapered surface)

- 22630.31~22630.34-dowel pin(Material: steel 、 SUS)(tapered surface)

- 22630.44~22630.47-dowel pin(Material: steel 、 SUS)(tapered surface)

- 22630.48~22630.51-dowel pin(Material: steel 、 SUS)(tapered surface)

- SGR771.1-dowel pin(Material: steel)

- SGR179-dowel pin(Material: steel)(Accessories: Special bushing for SGR771.1)

- SGR179.A SGR179.B SGR179.C-dowel pin(Material: steel)(Accessories: Special bushing for SGR771.1)

- SGR172-dowel pin(Material: steel)(Accessories: Special bushing for SGR771.1)

- SGR172.A SGR172.B SGR172.C-dowel pin(Material: steel、SUS)(Accessories: Special bushing for SGR771.1)

- 23110-dowel pin(Material: steel)(Accessories: Bushing)

- 24590-Spoke handwheel (material: aluminum)

- 24590-Spoke handwheel (rotary handle) (material: aluminum)

- 24590-Spoke handwheel (fixed handle) (material: aluminum)

- 24610-Spoke handwheel (material: aluminum)

- 24610-Spoke handwheel (rotary handle) (material: aluminum)

- SGR924.3-Spoke handwheel (folding rotary handle) (material: aluminum)

- SGR924-Spoke handwheel (material: aluminum)

- SGR924-Spoke handwheel (rotary handle) (material: aluminum)

- VRTP VRTP+I VRTP+IR-Plastic spoked handwheel (material: PP)

- NRP RP-Plastic spoked handwheel (material: PP)

- SGR949-Spoke handwheel (material: SUS)

- SGR949-Spoke handwheel (rotary handle) (material: SUS)

- GKS001 CRS.A SUSC.A-Precision Linear Shafts (Straight Type)

- GKS002 CRS.B SUSC.B-Precision Linear Shafts (Retaining Ring Grooves on Both Ends)

- GKS003 CRS.C SUSC.C-Precision Linear Shafts (One End Male Thread-Thread Diameter Equal to Shaft Diameter Type)

- GKS004 CRS.D SUSC.D-Precision Linear Shafts (Both Ends Male Thread-Thread Diameter Equal to Shaft Diameter Type)

- GKS005 CRS.E SUSC.E-Precision Linear Shafts (One End Female Thread Type)

- GKS006 CRS.F SUSC.F-Precision Linear Shafts (One End Female Thread with Wrench Flats)

- GKS007 CRS.G SUSC.G-Precision Linear Shafts (One End Male Thread Type)

- GKS008 CRS.H SUSC.H-Precision Linear Shafts (One End Male Thread with Wrench Flats)

- GKS009 CRS.K SUSC.K-Precision Linear Shafts (One End Male Thread with Undercut)

- GKS010 CRS.L SUSC.L-Precision Linear Shafts (One End Male Thread with Undercut and Wrench Flats)

- GKS011 CRS.M SUSC.M-Precision Linear Shafts (Both End Mate Thread)

- GKS012 CRS.N SUSC.N-Precision Linear Shafts (Both End Mate Thread with Wrench Flats)

- GKS013 CRS.P SUSC.P-Precision Linear Shafts (Both Ends Male Thread)

- GKS014 CRS.Q SUSC.Q-Precision Linear Shafts (Both Ends Male Thread with Wrench Flats)

- GKS015 CRS.R SUSC.R-Precision Linear Shafts (Both Ends Male Thread with Undercuts)

- GKS016 CRS.S SUSC.S-Precision Linear Shafts (Both Ends Male Thread with Undercuts and Wrench Flats)

- GKS017 CRS.T SUSC.T-Precision Linear Shafts (One Ends Male Thread/One End Female Thread)

- GKS018 CRS.U SUSC.U-Precision Linear Shafts (One Ends Male Thread/One End Female Thread with Wrench Flats)

- GKS019 CRS.V SUSC.V-Precision Linear Shafts (One Ends Male Thread/One End Female Thread with Undercut)

- GKS020 CRS.W SUSC.W-Precision Linear Shafts (One Ends Male Thread/One End Female Thread with Undercut and Wrench Flats)

- GKS021 CRS.X SUSC.X-Precision Linear Shafts (One End Stepped and Female Thread)

- GKS022 CRS.Y SUSC.Y-Precision Linear Shafts (One End Stepped and Female Thread with Wrench Flats)

- GKS023 CRS.Z SUSC.Z-Precision Linear Shafts (One End Stepped and Female Thread)

- GKS024 CRS.AB SUSC.AB-Precision Linear Shafts (One End Stepped and Female Thread with Wrench Fats)

- GKS025 CRS.AC SUSC.AC-Precision Linear Shafts (One End Stepped and Male Thread)

- GKS026 CRS.AD SUSC.AD-Precision Linear Shafts (One End Stepped and Female Thread/One End Male Thread)

- GKS027 CRS.AE SUSC.AE-Precision Linear Shafts (Both Ends Stepped)

- GKS028 CRS.AF SUSC.AF-Precision Linear Shafts (Both Ends Stepped and Female Thread)

- GKS029 CRS.AG SUSC.AG-Precision Linear Shafts (One End Tapered-One End Female Thread)

- GKS030 CRS.AH SUSC.AH-Precision Linear Shafts (One End Tapered-One End Male Thread)

- GKS031 CRS.AK SUSC.AK-Precision Linear Shafts (One End Tapered-One End Stepped and Female Thread)

- GKT003-Holders for Shaft (Standard Type/with Through Mounting Holes)

- GKT004-Holders for Shaft (Long Standard Type/with Through Mounting Holes)

- GKT005-Holders for Shaft (Standard Type/with Female Thread Mounting Holes)

- GKT006-Holders for Shaft (Standard Type/With Pilot Type)

- GKT007-Holders for Shaft (Standard Type/With Dowel Holes Type)

- GKT008-Holders for Shaft (Thicker Sleeve Type/Standard Type-With Through Mounting Holes)

- GKT009-Holders for Shaft (Thicker Sleeve Type/Long Sleeve Type-with Through Mounting Holes)

- GKT010-Holders for Shaft (Thicker Sleeve Type/With Pilot Type)

- GKT011-Holders for Shaft (Thicker Sleeve Type/With Dowel Holes Type)

- GKT018-Holders for Shaft (Thicker Sleeve Type/With Key Groove Type)

- GKT012-Holders for Shaft (Silt Type/Standard Type-With Through Mounting Holes)

- GKT013-Holders for Shaft (Silt Type/Long Standard Type-With Through Mounting Holes)

- GKT014-Holders for Shaft (Silt Type/With Pilot Type)

- GKT015-Holders for Shaft (Silt Type/With Dowel Holes Type)

- GKT019-Holders for Shaft (Silt Type/With Detachable Type)

- GKT016-Holders for Shaft (Round Type/Smaller Type)

- GKT017-Holders for Shaft (Round Type/Long Sleeve Type-Smaller Type)

- TPSH-Ball screw (flange round double cut, internal circulation)

- TPSH-Ball screw (rectangular, internal circulation)

- TPSH-Ball screw (rectangular, internal circulation)

- TPOH-Ball screw (flange round double cut, internal circulation, unprocessed shaft end)

- TPOH-Ball screw (rectangular, internal circulation, unprocessed shaft end)

- TPOH-Ball screw (square type, internal circulation, unprocessed shaft end)

- FSIW FSI FSB FSK-Ball screw (flange (double cut, single cut) round nut, inner circulation)

- FSC FSS-Ball screw (flange round double cut, internal circulation)

- BTM-MXL-Timing Belts(MXL)

- BOM-MXL-Timing Belts(MXL)

- BTM-XL-Timing Belts(XL)

- BOM-XL-Timing Belts(XL)

- BTM-L-Timing Belts(L)

- BOM-L-Timing Belts(L)

- BTM-H-Timing Belts(H)

- GBTM-S2M/S3M-Timing Belts(S2M/S3M)

- GBOM-S2M-Timing Belts(S2M)

- GBOM-S3M-Timing Belts(S3M)

- GBTM-S5M-Timing Belts(S5M)

- GBTM-S8M/S14M-Timing Belts(S8M/S14M)

- GBTM-P2M-Timing Belts(P2M)

- GBTM-P3M-Timing Belts(P3M)

- GBTM-P5M/P8M-Timing Belts(P5M/P8M)

- BBTO-T5-Timing Belts(T5)

- BBTO-T10-Timing Belts(T10)

- HTM-2GT-Timing Belts(2GT)

- HTM-3GT-Timing Belts(3GT)

- HTM-5GT-Timing Belts(5GT)

- HTM-8YU-Timing Belts(8YU)

- WBS、TBS、FBS、MBS、NBS、NBST、NBSS-Timing Pulleys(MXL)

- WBS、TBS、FBS、MBS、NBS、NBST、NBSS-Timing Pulleys(XL)

- WBSW、WBST、WBSF、WBSM、WBSB、WBS、WBSS-Timing Pulleys(L)

- WBSW、WBST、WBSF、WBSM、WBSB、WBS、WBSS-Timing Pulleys(H)

- GBSW、GBST、GBSF、GBSM、GBSB、GBSN、GBSS-Timing Pulleys(S2M)

- GBSW、GBST、GBSF、GBSM、GBSB、GBSN、GBSS-Timing Pulleys(S3M)

- GBSW、GBST、GBSF、GBSM、GBSB、GBSN、GBSS-Timing Pulleys(S5M)

- GBSW、GBST、GBSF、GBSM、GBSB、GBSN、GBSS-Timing Pulleys(S8M)

- GBSBMK、GBSNMK-Timing Pulleys(S14M)

- SBSW-Timing Pulleys(P2M)

- SBSW、SBSN、SBSS-Timing Pulleys(P3M)

- SBSW、SBST、SBSF、SBSM、SBSN、SBSS-Timing Pulleys(P5M)

- SBSW、SBSF、SBSM、SBSN、SBSS-Timing Pulleys(P8M)

- BBSW、BBST、BBSF、BBSM、BBSB、BBSN、BBSS-Timing Pulleys(T5)

- BBSW、BBST、BBSF、BBSM、BBSB、BBSN、BBSS-Timing Pulleys(T10)

- BBSW、BBST、BBSF、BBSM-Timing Pulleys(AT5)

- BBSW、BBST、BBSF、BBSM-Timing Pulleys(AT10)

- HSW-Timing Pulleys(1.5GT)

- HSW-Timing Pulleys(2GT)

- HSW、HSB、HSN-Timing Pulleys(3GT)

- HSW、HSB、HSN-Timing Pulleys(5GT)

- HSW、HSB、HSN-Timing Pulleys(8YU)

- WOL WOD-Ball Guide Post Sets for Die Sets(High density ball bushing)

- WTL WTD-Ball Guide Post Sets for Die Sets(High density ball bushing)

- WSL WSD-Ball Guide Post Sets for Die Sets(High density ball bushing)

- WYL WYD-Ball Guide Post Sets for Die Sets(High density ball bushing)

- WMC-Ball Guide Post Sets for Die Sets(High density ball bushing)

- WKC-Ball Guide Post Sets for Die Sets(High density ball bushing)

- ROL ROD ROR ROG-Ball Guide Post Sets for Die Sets

- RTL RTD RTR RTG-Ball Guide Post Sets for Die Sets

- RSL RSD RSR RSG-Ball Guide Post Sets for Die Sets

- RYL RYD RYR RYG-Ball Guide Post Sets for Die Sets

- RMC RMA-Ball Guide Post Sets for Die Sets

- RKC RKA-Ball Guide Post Sets for Die Sets

- SGR251.2-Positioning beads (material: steel) (with sensor)

- SGR615.7-Positioning beads (material: steel) (with sensor)

- 22030-Ball plungers (Material: Steel/SUS303) (Inner hexagon)

- 22031-Ball plungers (Material: Steel/SUS303) (Inner hexagon)

- BP SBP-Ball plungers (Material: Steel/SUS304) (Inner hexagon)

- 22030-Ball plungers (Material: Steel/SUS303) (Inner hexagon)

- 22050-Ball plungers (Material: Steel/SUS303) (slotted)

- 22050-Ball plungers (Material: SUS316) (slotted)

- MBP SMBP-Ball plungers (Material: Steel/SUS303) (slotted)

- 22050-Ball plungers (Material: Steel/SUS303) (slotted)

- 22051-Ball plungers (Material: Steel/SUS303) (slotted)

- 22040-Ball plungers (Material: POM) (slotted)

- 2B050-Ball plungers (Material: Steel/SUS303) (slotted)(inch)

- 22080-Ball plungers (Material: SUS303) (embedded type)

- 22080-Ball plungers (Material: SUS305) (embedded type)

- 22090-Ball plungers (Material: brass) (embedded type) (two-way)

- 22080-Ball plungers (Material: POM) (embedded type)

- 2B080-Ball plungers (Material: POM) (embedded type)(inch)

- 22080-Ball plungers (Material: SUS303/brass/POM) (embedded type)

- SGR614.1-Ball plungers accessories (Material: zinc alloy) (bracket)

- SGR250-Ball plungers accessories (Material: sintered steel) (V-shaped seat)

- SGR249.1-Ball plungers accessories (Material: steel) (fixed seat)

- TBT-Ball plungers accessories (Material: SK4) (fixed seat)

- 22075-Ball plungers (Material: steel/SUS303/POM) (collar type)

- 22051-Ball plungers (Material: SUS) (slotted)

- SPS-L SPS-H-Spring plungers (Material: steel) (Inner hexagon)

- 25010-Spring plungers (Material: SUS303) (built-in sensor connector)

- 25020-Spring plungers (Material: steel) (external sensor can be connected)

- 2B020-Spring plungers (Material: steel) (slotted)(inch)

- 2B020-Spring plungers (Material: SUS303) (slotted)(inch)

- 22050-Spring plungers (Material: Steel/SUS303) (slotted)

- 22030-Spring plungers (Material: Steel/SUS303) (Inner hexagon)

- 2B030-Spring plungers (Material: Steel) (Inner hexagon)(inch)

- 2B030-Spring plungers (Material: SUS303) (Inner hexagon)(inch)

- 22060-Spring plungers (Material: Steel/SUS303) (Inner hexagon)

- 22060-Spring plungers (Material: Steel/SUS303) (Inner hexagon) (dustproof)

- MBHC MBHF-Spring plungers (Material: S45C)

- MBHG MBHS-Spring plungers (Material: S45C)

- SJLF SJLTP SJHTP-Spring plungers (Material: S45C) (flat)

- NSP-L-Spring plungers (Material: S45C) (economical type)

- NSJS-N NSJL-N NSJH-N-Spring plungers (Material: S45C) (economical type)

- SJS-N SJL-N SJH-N SJX-N-Spring plungers (Material: S45C) (economical type)

- NSJS NSJL NSJH NSJX-Spring plungers (Material: S45C) (economical type)

- SJS SJL SJH SJX-Spring plungers (Material: S45C) (economical type)

- SP-H-Spring plungers (Material: SCM435)

- SP-L-Spring plungers (Material: SCM435)

- 22070-Spring plungers (Material: Steel/SUS303)

- 22070-Spring plungers (Material: Steel/SUS303) (embedded type)

- 22080-Spring plungers (Material: SUS305) (embedded type)

- SGR513-Spring plungers (Material: steel)

- 22100-Spring plungers (Material: Steel/SUS304) (simple type)

- 22150-Lateral plungers (Material: Aluminum) (embedded type)

- 22150-Lateral plungers (Material: Aluminum) (embedded type)

- 22150-Lateral plungers (Material: Aluminum) (embedded type)

- 22150-Lateral plungers (Material: Steel) (locking type)

- 22150-Lateral plungers (Material: Steel) (locking type)

- 22150-Lateral plungers (Material: Steel) (locking type)

- 22150-Lateral plungers (Material: Steel) (locking type)

- 22150-Lateral plungers (Material: Steel) (eccentric block)

- 22140-Lateral plungers (Material: Steel) (embedded type)

- 22160-Lateral plungers (Material: Steel) (locking type) (shrapnel type)

- 1009-Auto target group

- 22150-Lateral plungers (Material: Steel/SUS/POM) (embedded type)

- SGR8170-Index plungers (Material: SUS316) (Hygienic type)

- SGR8170-Index plungers (Material: SUS316) (Hygienic type)

- SGR817.6-Index Plungers (material: SUS303) (with sensor)

- SGR417-Index Plungers (material: zinc alloy) (flange type)

- SGR722.2-Index Plungers (material: steel / SUS316) (flange type)

- SGR722.3-Index Plungers (material: steel) (flange type)

- 22120-Index Plungers (material: steel) (flange type)

- 22120-Index Plungers (material: steel) (weldable)

- SGR612.3-Index Plungers (material: steel / SUS304) (weldable)

- SGR722.1-Index Plungers (material: steel) (weldable)

- 22120-Index Plungers (material: zinc alloy) (flange type)

- 22120-Index Plungers (material: steel) (with knob)

- SGR514-Index Plungers (material: steel) (press type)

- PMT.100-Index Plungers (material: PA) (with knob)

- PMT.101-Index Plungers (material: PA) (with knob)

- 22110-Index Plungers (material: steel / SUS303) (with knob / without knob)

- 22110-Index Plungers (material: steel) (with knob)

- SGR817-Index Plungers (material: steel / SUS303) (with knob)

- SGR817-Index Plungers (material: steel / SUS303) (with knob)

- SGR818-Index Plungers (material: SUS316) (with knob)

- SGR818-Index Plungers (material: SUS316) (with knob)

- 22120-Index Plungers (material: SUS303) (with knob)

- 22120-Index Plungers (material: SUS303) (with knob)

- 22120-Index Plungers (material: SUS303) (with knob)

- 22120-Index Plungers (material: steel / SUS303) (with knob)

- 22120-Index Plungers (material: steel / SUS303) (with knob)

- 22120-Index Plungers (material: steel / SUS303) (with knob)

- 22120-Index Plungers (material: steel / SUS303) (with knob)

- 22120-Index Plungers (material: steel / SUS303) (with knob / without knob)

- 22120-Index Plungers (material: steel / SUS303) (without knob)

- 22120-Index Plungers (material: steel / SUS303)

- 22120-Index Plungers (material: steel / SUS303)

- 22130-Index Plungers (material: steel) (precision type)

- 22130-Index Plungers (material: steel) (precision type)

- SGR7336.7-Index Plungers (material: steel) (with knob)

- 1087-Index Plungers (material: steel) (with knob)

- SGR816.1-Index Plungers (material: steel) (pin built-in type)

- SGR816-Index Plungers (material: steel) (pin extension type)

- 22120-Index Plungers (material: steel / SUS303) (with knob) (short type)

- SGR822.1-Index Plungers (material: steel / SUS303) (with knob) (short type)

- SGR7336.8-Index Plungers (material: steel) (with knob) (short type)

- 22110-Index Plungers (material: steel / SUS303) (with knob) (short type)

- SGR822-Index Plungers (material: steel / SUS303) (with knob) (short type)

- SGR612.8-Index Plungers (material: zinc alloy) (short type)

- SGR609.5-Index Plungers (material: SUS303) (accessory: adjusting ring)

- SGR712.1-Index Plungers (material: steel) (pin built-in type)

- SGR712-Index Plungers (material: steel) (pin extension type)

- SGR412.1-Index Plungers (material: zinc alloy) (accessory: support seat)

- SGR412.2 SGR412.4-Index Plungers (material: steel / SUS431) (accessory: bushing)

- SGR412.3 SGR412.5-Index Plungers (material: steel / SUS431) (accessory: beveled bushing)

- SGR414-Index Plungers (material: steel)

- SGR817.3-Index Plungers (material: steel) (with knob)

Gasket is a kind of sealing spare parts used in machinery, equipment and pipelines as long as there is fluid. It uses internal and external materials to play a sealing role.

Important 4 factors affecting gasket selection (temperature, application, medium, pressure)

Standard of use of rubber gasket:

1. Good elasticity and recovery

2. Can fit well with the contact surface

3. Does not pollute the medium

4. No hardening at low temperature

5. Small shrinkage and easy disassembly.

●Product introduction

Features of Gaskets

1. Has excellent leak-proof function.

2. Excellent oil resistance, heat resistance and weather resistance

3. Can be used repeatedly (2 to 3 times).

4. Excellent usability.

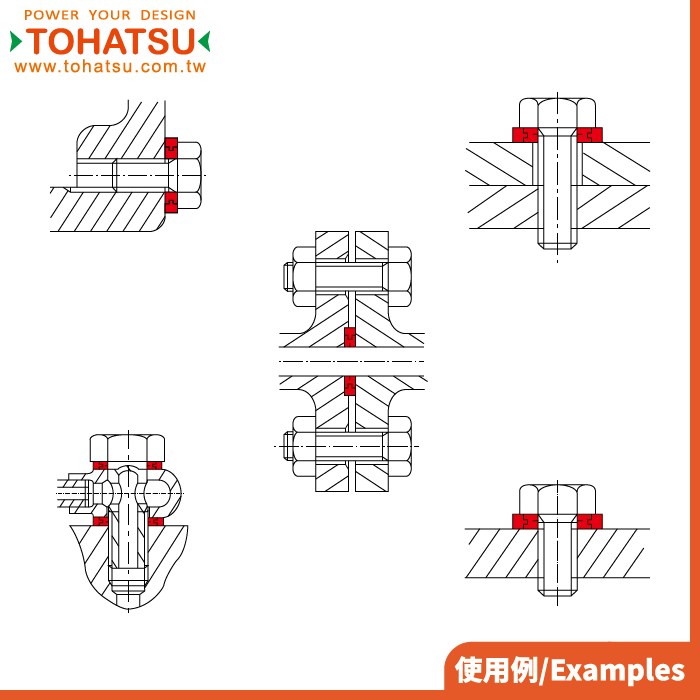

When using ferrules, there is no need to distinguish between front and back.

Even if the gasket is installed in the screw, turn the screw down and it will not come off.

●Precautions for use

1. Aperture:

Standard type I uses JIS B 1001 bolt hole diameter class 2 or less, and chamfered thread chamfer (approximately C0.2).

Standard II type and nut type, use JIS B 1001 bolt hole diameter class 1 or less, chamfered thread chamfer (about C0.2).

2. Surface roughness of the contact surface of the mounting part:

According to JIS B 0601, the finish of the contact surface of the gasket mounting portion should be 10 μmRz or less.

3. Applicable temperature:

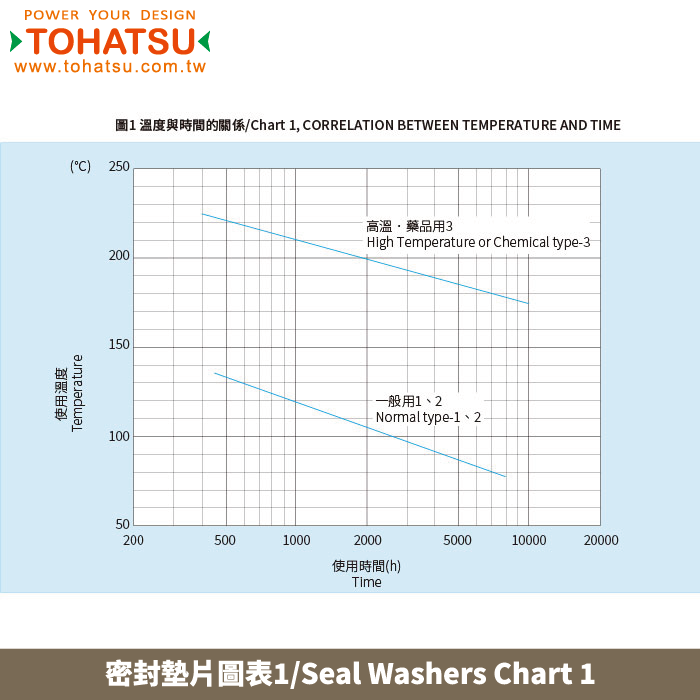

This depends on the type of gasket and the conditions of use. Figure 1 shows an example of the relationship between operating temperature and operating time.

4. Working limit pressure:

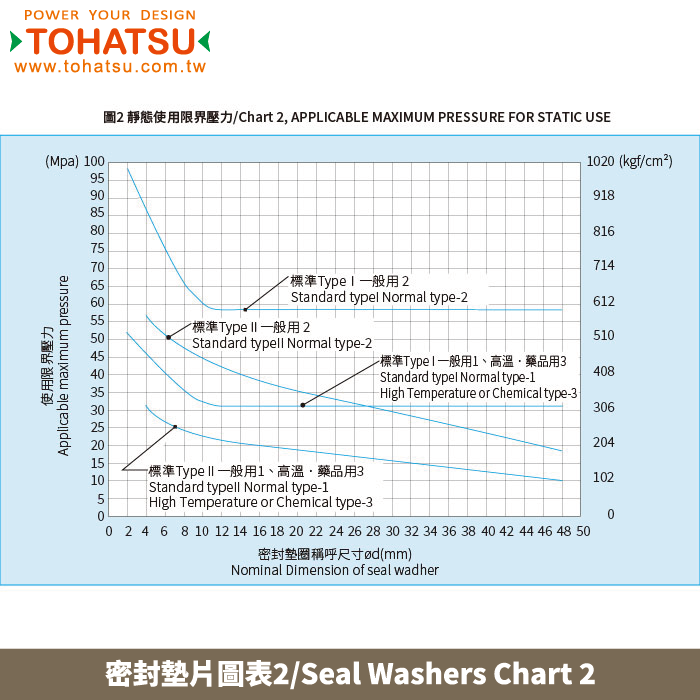

It depends on the type and size of the gasket.

1) Figure 2 shows examples of working limit pressures using standard Types I, II and III static pressures. When used under fluctuating pressure, the working limit pressure should be the static working limit pressure × 0.4 times.

2) Thread use type

Regardless of size, the working ultimate pressure should be 294 kPa {3 kgf/cm2}.

5. Tightening torque

Gasket tightening torque may vary depending on gasket type, screw type used, lubrication conditions and tightening speed.

6. The thread type cannot be used for screws and bolts with different pitches.

7. The SUS304 core metal used in our gaskets is generally non-magnetic, but may show magnetic properties due to press processing.

8. Since the oil (liquid) used, the environment of use, the conditions of use and installation conditions will have different effects on the function of the product, it is recommended that customers check before use.

●Save the precautions for use

1. Store in a cool and dark place, avoid direct sunlight and high temperature (40℃ or higher).

2. Be careful not to damage the rubber part when assembling.

3. It is recommended to use it up within two years