1YRS

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Products

5-Axis Vertical Machining Center

UV650 5-Axis Vertical Machining Center

UV系列

UV series - High Performance 5-axis Vertical Machining Center, multiple industries such as job shop, medical, aerospace, and die & mold.

Simultenous 5-Axis VMC for Complex Parts

Specification

Robust Structure Design

- High Quality, Rugged MEEHANITE™ Castings – YCM's In-House Foundry follows strict international MEEHANITE standards ensuring high stiffness, rigidity, and vibration dampening that results in superior thermal stability, and cutting performance.

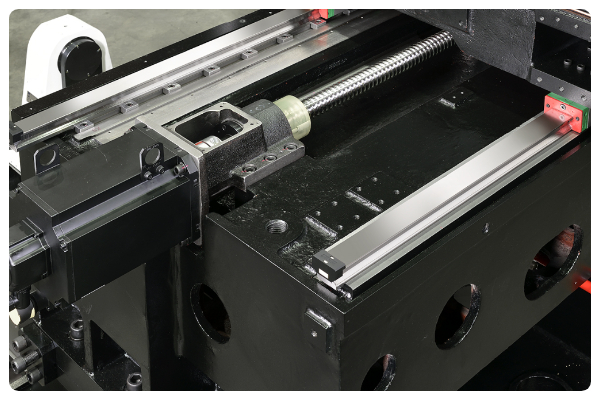

- Reinforced saddle features provides optimum stiffness, rigidity and stability.

- Extra wide base and column design enables solid support and excellent cutting performance when machining complex parts at a high feeds and speeds.

Accurate and Thermally

- Linear scales are mounted in X/Y/Z-axis and encoders in the B & C axis allowing for the most demanding machining accuracies.

- The X/Y/Z-axis are fitted with high precision roller guideways and fixed pre-tensioned, double-nut, direct drive ballscrews, allowing for fast and accurate machining.

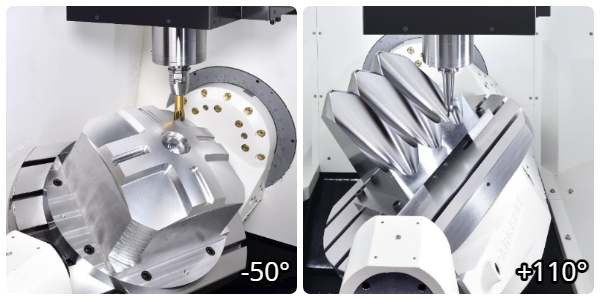

B/C-axis Rotary Table

- High precision rotary encoders in the B and C

- axes as a standard feature, allowing for the most demanding machining accuracies.

- Durable 2-axis tilt/rotary table allows fast, accurate

- machining of complex 5-axis components.

- The tilt-rotary table features a full circular hydraulic braking system that provides rigid B/C-axis clamping during fixed rotary-axis machining applications.

YCM In-house IDD Spindle

- The YCM IDD spindle design provides power, speed, and stiffness required for the

- most adverse machining applications while providing long spindle life.

- Ceramic bearings help to minimize heat and provide thermal stability improving overall

- machining accuracy.

- Powerful 17 kW max. hollow shaft spindle motor – allows machining of the toughest

- materials, while also providing with fine surface finishes and the ability to add up to

- CTS 20 bar (1,000 psi) coolant through spindle (CTS) easily.

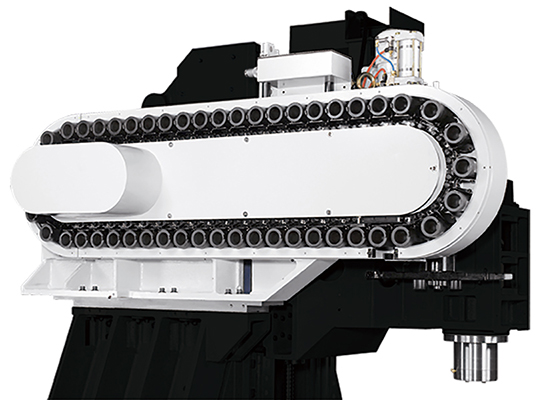

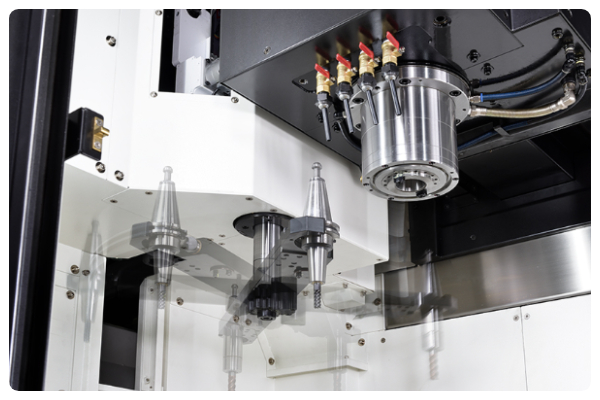

Tool Magazine

- Chain type 40T magazine as standard

- Wide selection of optional tool magazine, including 48T / 60T

- Absolute encoder ATC system tracks tool pot position in the event of a mishap

Automatic Tool Changer

- Tool to Tool time: 1.8 sec.

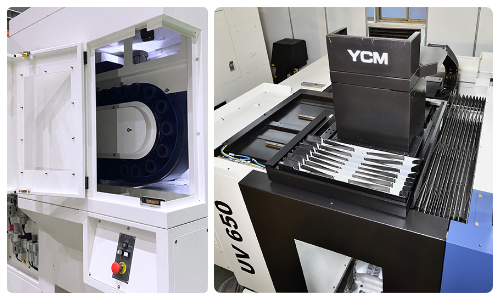

- Standard ATC auto door minimizes chips and coolant from entering the tool magazine area.

- This design incorporates an inverter type cam-box-motor for easy ATC recovery in the event of a mishap. The tool change arm is designed for low inertia allowing precise positioning and long service life.

Chip Removal

- 4-coolant lock lines around the spindle, 2-coolant lock lines on the right side of the spindle, cutting air-blast with 1-lock line on the right side of spindle, coolant gun, and air gun.

- Standard shower coolant nozzles mounted from the roof and saddle provide optimal chip removal.

- Efficient chip discharge with steep angle allow unhindered chip flow to the chip conveyor.

User-friendly Operation

- Large front and right side doors allowing easy reach and unrestricted access.

- Optional right side automatic door can be selected to combine with robot, gantry, or pallet allowing for automated unmanned operation.

- The controller allows 145-degree swivel movement and can be operated at the front or right side of the machine.

- Bellows type roof-top cover ensures chip and coolant containment. The middle section can also be easily and automatically unlatched and moved back on a track

- when loading heavy parts on the table with an overhead crane.

- Easy operator access to the tool magazine for the quick change of tools.