1YRS

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Products

Horizontal Machining Center

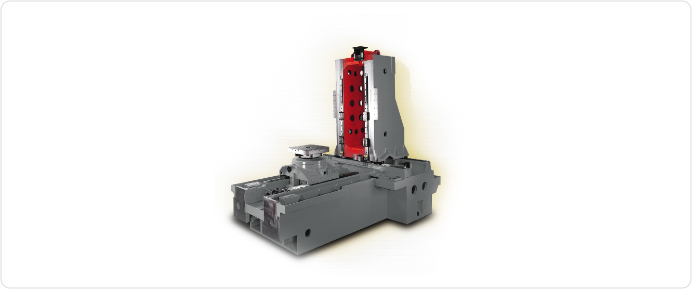

H500B Horizontal Machining Center

H系列

H series - Heavy Duty HMC for General and Hard to Machine Materials.

Specification

High Rigidity Construction With High Feedrate

- The moving column design, the strengthened 3-point support base, and dual wall rib-structure designed column sustain the utmost rigidity, accuracy level, and machine durability.

- Direct transmission design on all 3 Axes and pre-tensioned ballscrews ensure motion rigidity, and machining accuracy.

- Deploy high precision linear motion guideways, ensure excellent machining performance and service life with low friction, high rigidity, high speed and optimal damping force. The rapid feedrate is 40 m/min. (X/Y/Z), and 20 m/min. for max. cutting feedrate.

High Speed, High Precision Spindle Design

- Ceramic spindle bearings for high speed machining, features low thermal expansion coefficient and excellent rigidity performance.

- The ID’s of spindle bearings, ø100 mm ø3.94", satisfy heavy cutting requirements.

- Standard isolated direct drive (IDD) 6,000 rpm spindle with BBT50 taper, offers excellent power output.

- High-Low speed winding performs 36 kgf-m 260.39 lb-ft and excellent cutting capability.

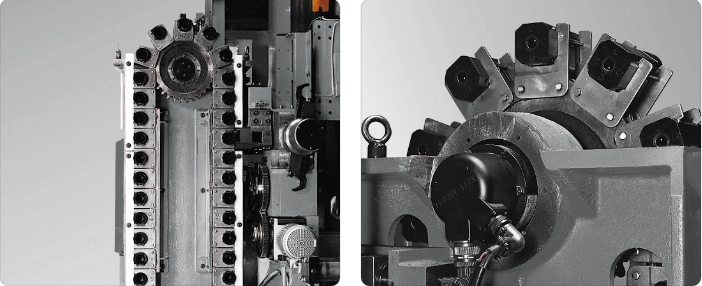

Quick and Reliable ATC Mechanism

- The roller-gear-cam ATC arm, parallel to the spindle of the short-pitch design, makes the ATC prompt and reliable; it takes only 2.9 sec.

- The magazine is precisely indexed and driven by servo motor for efficient operations.

High precision, power clamp APC enhances flexibility and efficiency

- Compact and smart rotary pallet change design with unique and strengthen rail way support ensures the accurate, fast, and reliable APC.

- Pallet is swift (on Z-axis) to make APC, the rotary door is quickly turned along with APC, which takes only 10 sec.

- Large size ø450 mm ø17.72" position clutch is deployed, together with taper pin in precise positioning, strongly supports the table and meets the rigid machining needs.

- Optional 0.001° continuous feed 4th axis pallet of dual warm gear design is backlash-free and easily maintained.