1YRS

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Products

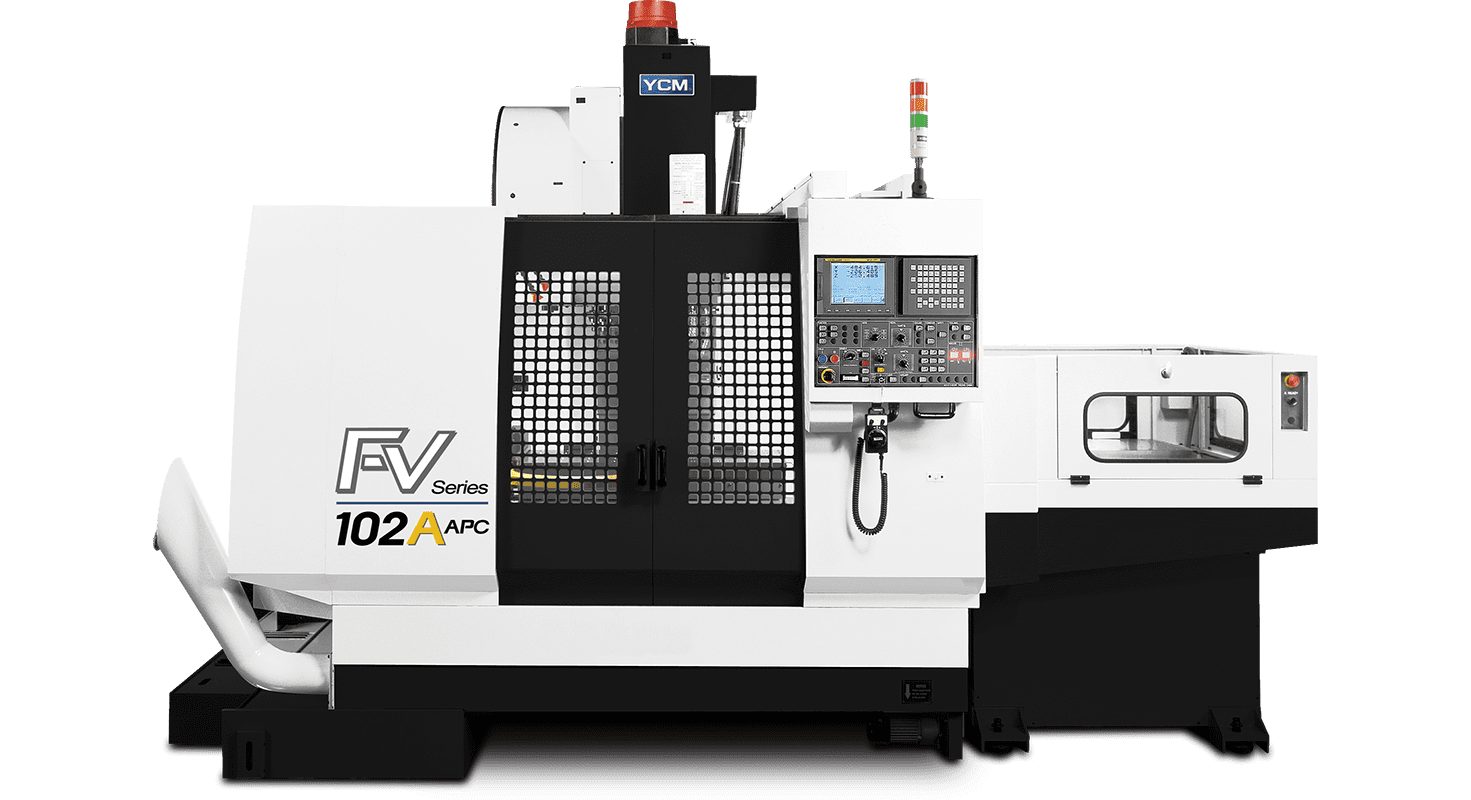

Vertical Machining Center

FV102A-APC Vertical Machining Center

FV系列

FV series - Speed and Power in a Compact VMC. Well Suited for Mold Work.

Specification

Hi-Speed, Hi-Power Spindle Design

- The 10,000rpm spindle deploys precision ceramic ball bearings of light mass, low centrifugal force, low swell factor, but high rigidity, which assure the optimal accuracy and spindle life span.

- Oil-Air lubrication 12,000rpm or 15,000rpm spindle is available for option.

Reliable ATC Unit

- Fast and reliable roller gear cam ATC allows ATC time in 3.5 seconds, lower the idle time and enhances the machining efficiency.

- The ATC units were running tested more than 72 hours before their mass production to ensure high reliability.

Complete chips disposal system

- Ensure the cleanness of the machining environment. Optional flush coolant can be used to prove the chips disposal efficiently.

- Screw type chip conveyor makes the chips disposal more easily & efficiently.

- Complete set of the Y-axis back side plate well protects the guide-way for durable operation.

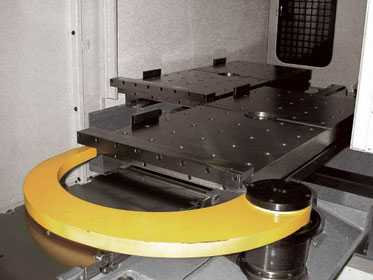

Shuttle Type Automatic Pallet Changer

- APC's swivel arm is driven by X-axis servo motor with unique rack transmission design, features fast and accurate pallet change mechanism.

- APC time is around 15 seconds.

- Oversized taper pins are applied to ensure backlash-free positioning and rigid clamping on the pallet.

- APC feed rate is adjustable to appropriate speed for different workpieces' demand.

Super-Accuracy & Rigidity Construction for High Speed Epoch

- Tough and durable MEEHANITE castings deliver exceptional cutting stability and consistent accuracy - the massive, rigid internally ribbed construction reduces damping effect for superb part finishing.

- The extra wide column base and machine base maximize the cutting rigidity, and enhance machine stability during heavy-duty machining.

- Hardened & ground ballscrews are precisely pre-tensioned at both ends, supported by angular contact thrust bearings, and directly coupled with high responsive AC servomotors of backlash-free for outstanding positioning repeatability and accuracy during long machining cycles.

- All axes utilize the newly developed NR type linear motion guide ways of its superior rigidity, low friction, low noise, thus to assure much smoother movement in high-speed traverse.

- All linear motion guide ways are mounted on the very fine surface for maximum surface contact and exceptional cutting rigidity and stability.