Products

With the continuous improvement of the metal processing industry requirements, high hard materials processing needs increased, and the workpiece miniaturization, fast high precision, high finish, quality and stability has become the basic requirements. In this context, KINIK company manufacture single crystal, PCD and PcBN endmills and cutting tools to fit customer need.

Applications:

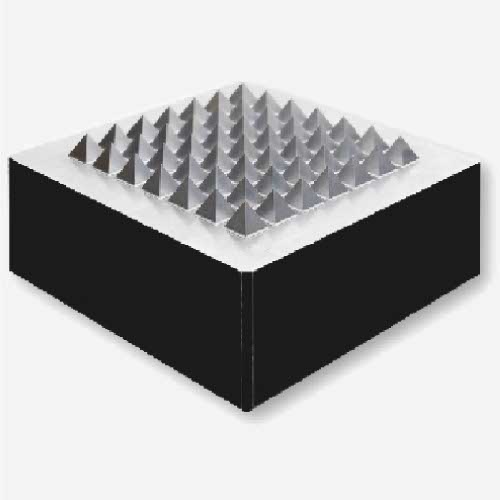

Precision molding of 3C industry, such as for LED lead frame molds, for cell phone housing and for handle of PS game machine.

Precision molding of optoelectronic, such as for LED and optical lens.

The mold of auto lamp, gear wheel.

Features:

Suitable for HRC 50+ and high hardened steels.

Outstanding attrition resistance and illumination of mirror.

Compared with carbide tools, feed rate raises and life time increases several times.

R-accuracy less than +- 5μm

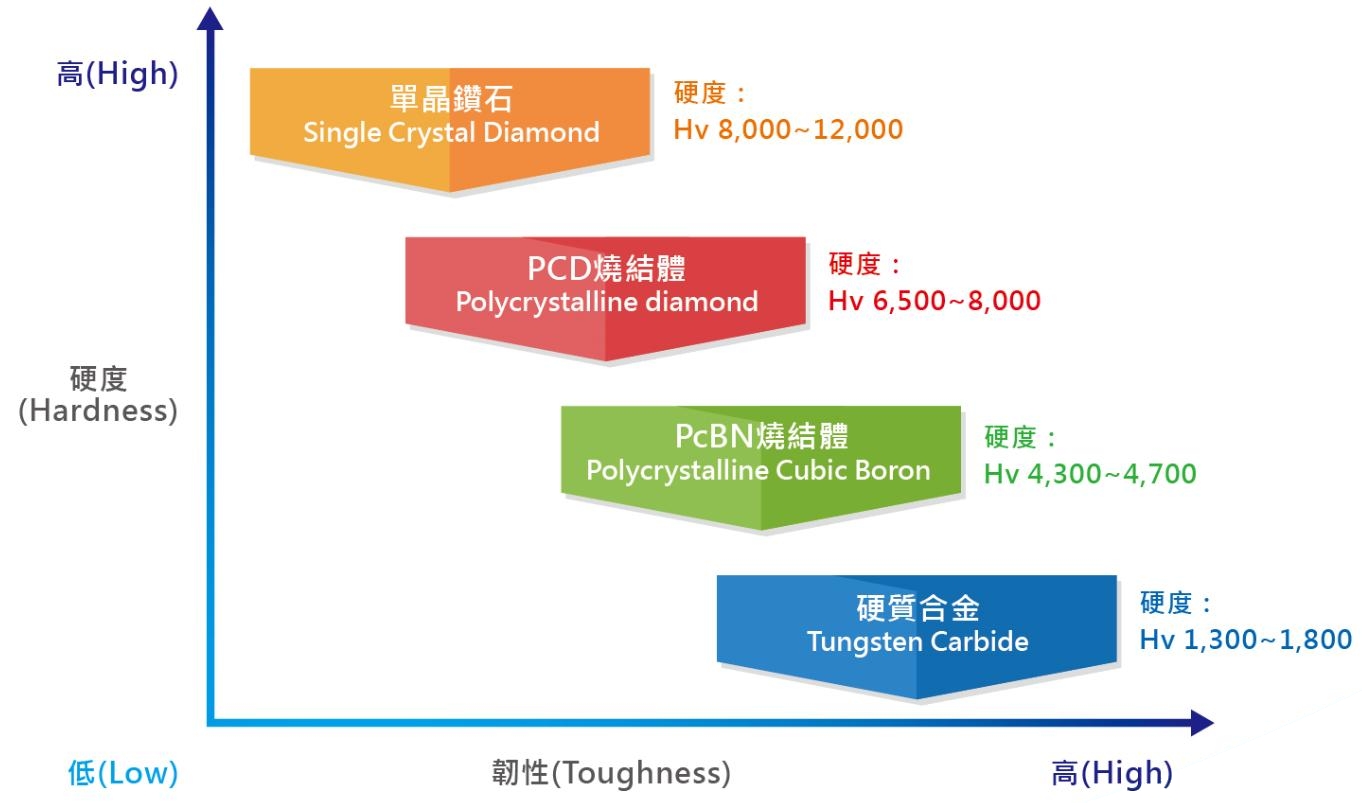

PcBN/PCD/SCD

PcBN:

The hardness of CBN(Cubic Boron Nitride) is second to diamond, which is about three times harder than the cemented carbide. CBN is a tool material with high heat resistance and high thermal conductivity, but with low toughness and easy to break. The cutting edge will easy chipping for the rough process because of the higher resistance to cutting edge. However, because of the high hardness, high heat resistance and low wear characteristics, CBN is more suitable for fine finishing of high hardness materials. The tool life, the roughness of the workpiece and homogeneous of CBN tools are superior to cemented carbide tools.

PCD:

PCD is made from synthetic diamond powder, which sintered under high temperature, high pressure sintered polymer, it is also known as polycrystalline diamond. As the same as single crystal diamonds, PCD is with high hardness and high wear resistance characteristics, but the heat resistance of the material is poor and not suitable for ferrous[based materials process. PCD is particularly suitable for non[ferrous material cutting (such as : Graphite, wood, aluminum, copper and composite materials).

SCD:

Single Crystal Diamond Tool is using the hardest material on earth - diamonds (natural diamond ND and artificial diamond MD, CVD). As this material is a single crystal, in the ultra-fine processing, you can get a perfect edge shape (No Chipping). Single crystal tool is particularly suitable for mirror finishing, and a good surface roughness (Ra 0.05μm below).

Ballnose Endmill

Ballnose Endmill is the best choice for arc, curved surface process. Our best process capability of the minimal radius R0.05 on cutting edge can meet customers' high standard process requirement. We also can produce bigger radius cutting edge tool as request. Our ballnose endmill of various specification can satisfy customers' all kinds of requirements.

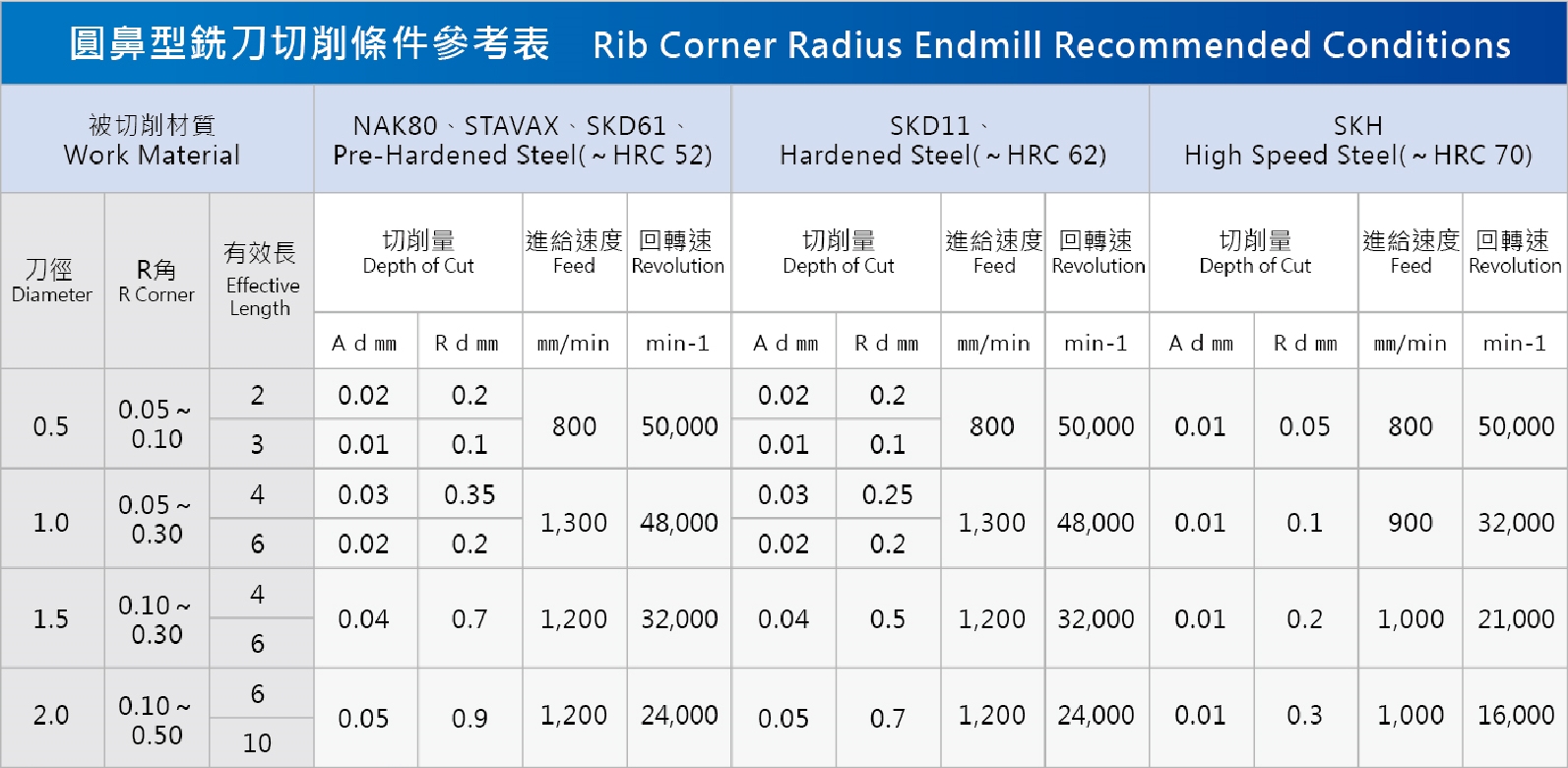

Rib Corner Radius Endmill

Rib corner radius endmill is one of the most popular cutting tool, which is used for the process of right angle or flat bottom of work piece. Our best process capability of the minimal radius R0.01 and none radius endmill can be used for various, customized process and satisfy customers’ all kinds of requirements.

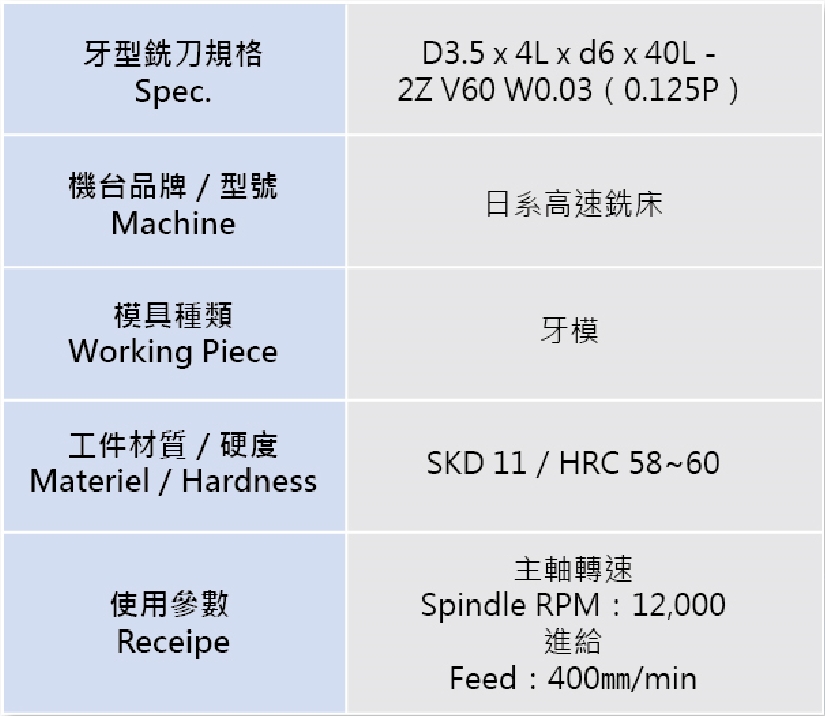

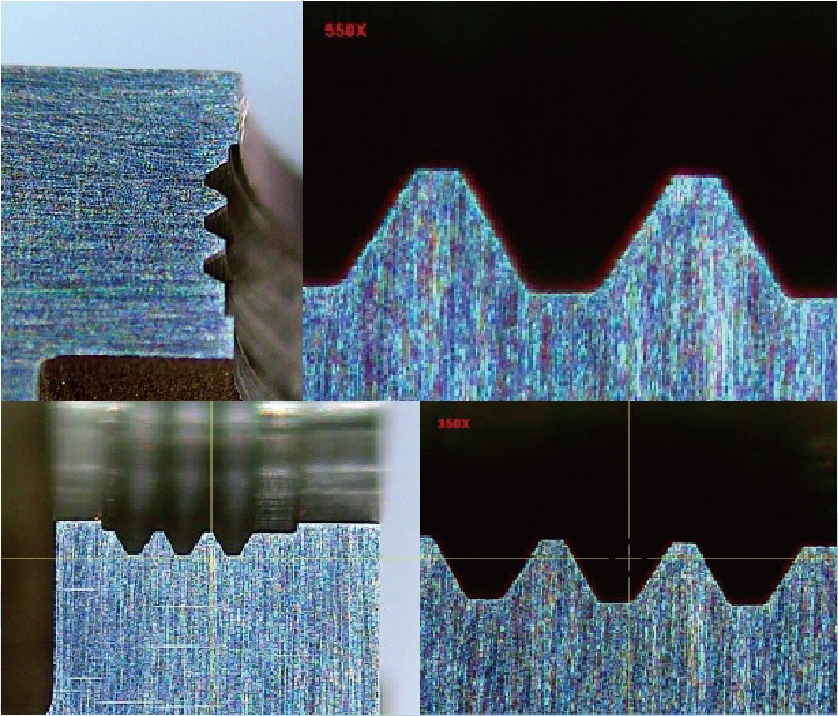

Thread & T-type Endmill

We all know that the parts of essential lens mould set of mobile device & vehicle camera must be produced by very precise and accurate mould. KINIK's PcBN thread & t-type endmill is the best weapon to process such kind of moulds. High process speed, long tool life, and uniform mould quality are the outstanding advantages of our tools, which can achieve the best effect.