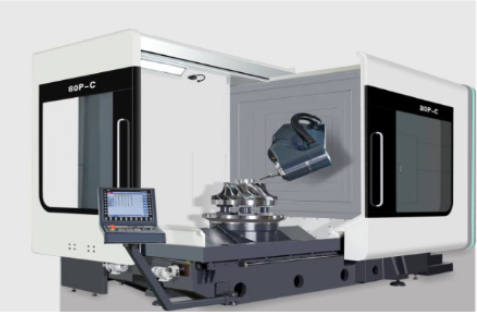

Products

1 brief introduction of machine performance

Technical specifications of main machines | best configuration of rigid structure

Design features | analysis and design of the best mechanical line casting

The structure of full box hot symmetrical casting is made of high-grade cast iron of milhanna grade

The internal stress can be eliminated by tempering and natural aging

The natural frequency vibration of the structure can eliminate the processing stress of the material

The overall wall large area high rigid column design can effectively improve the rigidity, static and dynamic accuracy

Three axis hollow cooling screw drive

CNC swing milling head (b-axis)

Design features

Design of Zero drive chain without backlash for built-in DD motor

High acceleration characteristics

The shortest span between the tool tip point of spindle and the structural support point can achieve the maximum rigidity of cutting

Larger YRT bearing improves rigidity

Equipped with Heidenhain high precision rotary encoder measurement system, full closed-loop control, to ensure the best accuracy

Design of cooling system for spindle and b-axis to reduce heat transfer

Rotary table (c-axis)

Design features

Design of Zero drive chain without backlash for built-in DD motor

High acceleration and deceleration response characteristics

Larger YRT bearing improves rigidity

Large rated driving torque, positioning processing, with positioning clamping device of worktable

It can meet the needs of milling and turning, reduce the handling of workpieces and improve the accuracy of products

Equipped with Heidenhain high precision rotary encoder measurement system, full closed-loop control, to ensure the best accuracy

Design of cooling system to reduce heat transfer

Adjustable tool setting instrument

Design features

It is equipped with ransishaw nc4f230 non-contact laser tool setting instrument with higher precision

Automatic tool setting and tool compensation update

The tool setting device can be raised and lowered to save the space of machining surface

The fully sealed sheet metal design protects the tool setting instrument from water and iron chips during processing

Infrared probe

Design features

It is equipped with ransishaw OMP60 trigger optical probe

The alignment and size detection of on-line workpiece can reduce manual detection error and improve product accuracy and processing efficiency

On line auxiliary time saved by 90%

Safety sheet metal

appearance

This series of 5-axis milling and turning compound machining center cover is designed in accordance with strict CE safety standards. It uses fully closed sheet metal to prevent operators from entering the operation range during processing, and prevent the use of high-pressure cutting fluid or chips from spraying out of the machine. In addition to the warning plate, the operation door is also equipped with a safety switch to prevent accidents during operation or maintenance. And has a large peep window, convenient for the operator to understand the operation of the machine processing.

clean

The expansion shield and protective sheet metal are used to protect the chips generated during operation, so as to avoid the damage of other mechanisms caused by cutting spatter.

lighting

The working area is equipped with two LED lights, and the illumination is maintained above 800Lux, providing a suitable bright working environment for the operator.

Operability

The operation side is equipped with a split sliding door to provide a large open space for the workpiece to be loaded and unloaded from three directions by using the crown block freely.

2. Main components and brands

Standard accessories menu

Function list of standard accessories (please refer to controller function for electric control part)

Configuration of Jinling 80p-c five axis milling and turning compound machining center

1. Siemens 840dsl top level system controller of five axis linkage belt turning and milling

2. Jinling five axis multifunctional swing head

3. Jinling motorized spindle dgzx-24012 / 34b2-kfhwvjs

4. Hsk-a63 40 tool magazine automatic tool change system (optional □)

5. X / Y / z-nsk C3 hollow cooling ball screw drive

6. 7 roller linear slide rails (3 for x-axis and 2 for Y / Z-axis) - Bosch Rexroth up

7. X / Y / Z three axis full closed loop optical ruler

8. Temperature control device of electric box

9. Spindle cooler

10. Screw chip coiling device and rear iron chip conveyor with iron chip car (optional □)

11. The main shaft center water, annular spray

12. The main shaft center blow air, annular blow air

13. Five axis head crescent blow water, crescent blow air

14. One front and one side work door safety interlock

15. Spindle circulating cooling device

16. Waterproof working fluorescent lamp

17. Jinling hydraulic station

18. Renishaw OMP60 infrared probe device

19. Renishaw laser tool setting device

20. Central centralized automatic feed lubrication device

21. Clean the water gun and air interface on the operation side

22. Cutting fluid cooling system

23. Fully enclosed protective sheet metal

24. Operation box

25. The electric box is equipped with air conditioner

26. Siemens electronic hand wheel

27. Pedal spindle tool release switch

28. Foundation horizontal cushion block and foundation bolt

29. Adjustment tools and toolbox

30. Technical Manual