Products

Ceramic tool should pay attention to the use of:

1 stability is better

Including the workpiece clamping, the rigidity of the machine, the use of ceramic blade special tool, and the cutter head to minimize the distance to the minimum.

2 select the maximum cut in angle

Under the potential range, the cutting stress can be dispersed on the longer cutting edge, thus reducing the unit

Length of cutting stress.

3 use correct cutting data

4 choose the right edge shape

The hard brittleness of ceramic tools makes the shape of the blade, which is strictly restricted.

|

Names |

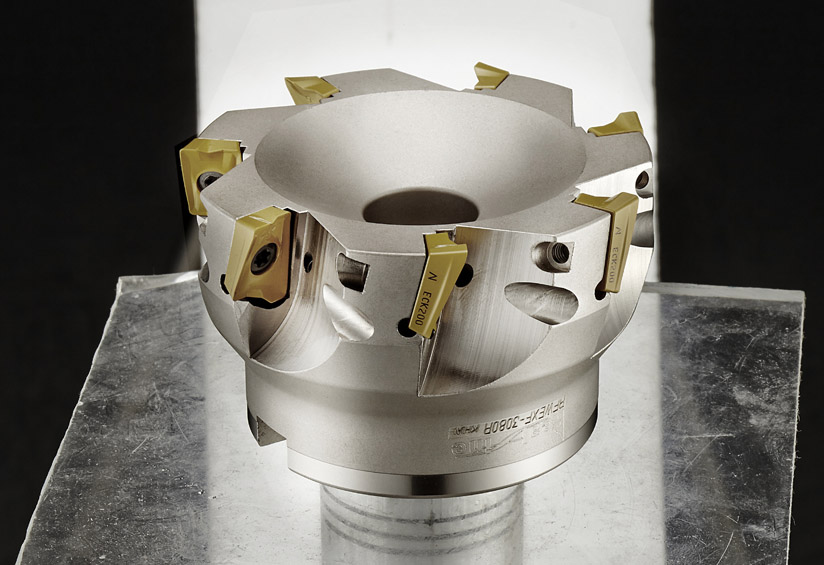

Inserted Ceramics tools – Milling |

|

Materials |

Thermal hardness, Toughness, Low thermal-expansion efficiency |

|

Hardness |

HV |

|

Property |

Carbon steel, Alloy steel, Stainless |