Products

The impact of the chip not being removed and cleaned in time: The chip conveyor will take away the chips when the cutting fluid is processed, but some of the uncarried waste debris will be left at the bottom of the water tank, which will generate anaerobic bacteria 、cause the release of odor 、 the acidification of the cutting fluid and the drop of Ph value make the cutting fluid deteriorate; it also reduces the effective volume of the water tank, resulting in insufficient water supply.

The FC series chip vacuum machine uses the principle of negative pressure vacuum in exchange for a large suction volume, and then achieves continuous filtration to intercept impurities and suspended particles. Whether it is all oily cutting fluid or water-based cutting fluid, it can intercept iron filings, aluminum mud, aluminum filings , Copper powder, aluminum powder, tungsten steel powder, stone mill... etc. And there is no cost of consumables. It can save the time and labor cost of the clean water tank. It is a high CP value chip suction machine.

Widely used in lathes, milling machines, grinders, drilling machines, CNC, boring machines, planers, sawing machines, broaching machines and other machine tools to effectively remove impurities in the water tank.

Continuous processing/non-batch processing/no need to worry about running out of water in the tank

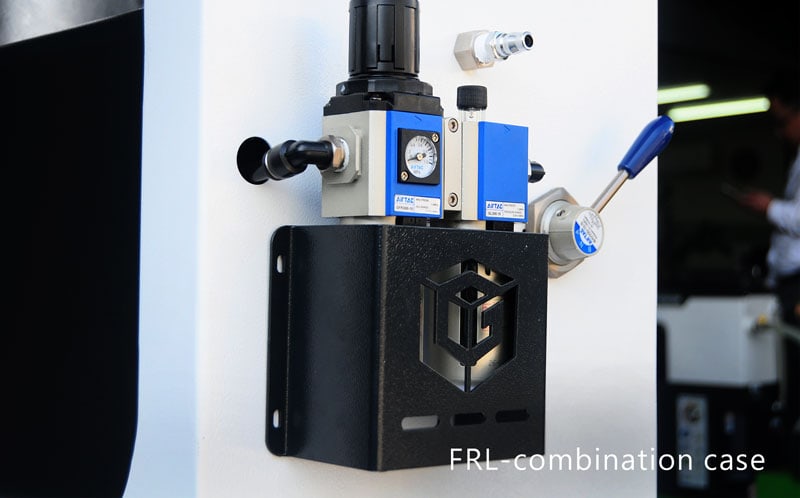

No need to use electric/pneumatic pump/high safety

No downtime/increased capacity

Dehydrate/reduce water content

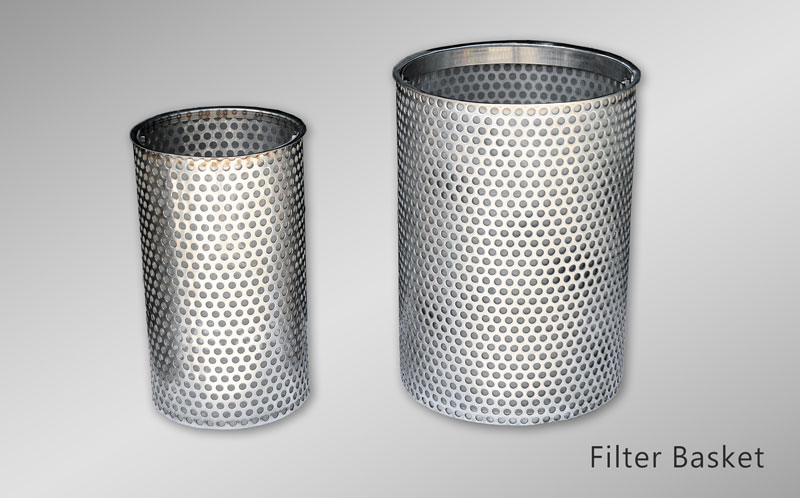

No consumables/stainless steel filter basket can be cleaned

Save cutting fluid consumption

Increase the effective volume of the water tank

Increase production utilization rate

Features

Promote Volume of Water Tank

- Empty space promotes 40% efficiently

Reduce manual work

- Lower 15% of the cost, Increase Value of output

No consumable

- Cost down & Use more earn more

CNC Machine No need to Stop

- Promote productivity 50%, get High efficacy target

Specification

| Model | FC180 | FC180 Plus | FC380 | Unit |

|---|---|---|---|---|

| Dimension | 810*370*730 | 810*370*750 | 990*430*750 | mm |

| Net Weight | 56 | 63 | 71 | kg |

| Filter Tank capacity | 7 | 17 | 17 | L |

| Air pressure | 5 | 5 | 5 | bar |

| Maximum Air consumption | 1200 | 1200 | 2400 | l/min |

| Maximum Negative pressure | 55 | 55 | 69 | kg/m3 |

| Fluid volume | 180 | 180 | 380 | l/min |

| Filter Precision | 380 | μm | ||

| Suggest air supply caliber | 3/8 | 3/8 | 1/2 | inch |

*If purchase the filter basket, 180μm or 380μm of filter basket can be optional.