Products

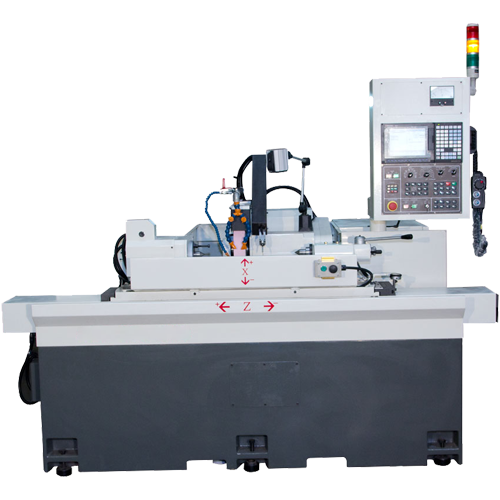

Hydrodynamic spindle

Rotary center / Fixed center head stock

Manual/Hydraulic tailstock

CNC control system

Grinding cycle

Grinding wheel dressing cycle

High Precision,Sturdy & Durable,Waterproof & Dust-proof,Easy Operation

Hydropdynamic spindle

The grinding wheel spindle is made of high-grade alloy steel (SNCM220) by precision machining, including multiple heat treatment, grinding, polishing, ect. for its durability. The spindle is supported by unique hydrodynamic bearing to reach excellent rigidity and shock resistance.(End measuring device is optional)

Rotary center/Fixec center head stock

The simple and stable head stock is equipped with high-precision bearing, which greatly improves the rigidity and rotation precision of the spindle. Excellent waterproof ability enhances the durability of the machine.

Manua/Hydraulic tailstock

The oil-filled type Iubrication system of tailstock consolidates, and ensures the high-precision of tailstock.

CNC control system

It is equipped with advanced CNC controller and form-filling type operation interface, and has editable standard grinding cycle program. It can also customize the dressing shape for special grinding request. It is easy to learn and understand.

Grinding cycle diagram

Grinding wheel profile

Multi-plunge traverse grinding

Overview of grinding wheel profile

Grinding cycle

Notes: 1.By separate setting for grinding cycle, the grinding cycle can be divided into rough grinding, medium grinding fine grinding and spark-out grinding.

2.With an automatic measuring device for outer diameter(optional), the grinding volume can be set for plunge or angular grinding.

Grinding wheel dressing cycle

Notes: 1.Diamond dressers can be set up to 5.

2.There are five profile selections for grindind wheel dressing. Both sides can be dressed.

3.Support customized profile setting function with graphical display, up to 40 points.

Dimensions of CNC cylindrical grinder

| SN | 400 Series | 600 Series | 800 Series |

| A | 1700 | 2100 | 2500 |

| B | 590 | 610 | 630 |

| C | 630 | 650 | 670 |

| D | 2920 | 3360 | 3800 |

| E | 355 | 555 | 755 |

| F | 495 | 695 | 895 |

Plunge type GP27 Series

|

MODLE |

GP27 / 35-400CNC | GP27 / 35-600CNC | GP27 / 35-800CNC | ||

|---|---|---|---|---|---|

|

Work |

Maximum grinding diameter | mm | 270/350 | ||

| Distance between centers | GP | 400 | 600 | 800 | |

| Distance from spindle hole center to the slide | mm | 136/176 | |||

|

Maximum workpiece weight |

kgs | 120/150 | |||

|

Grinding |

Grinding wheel size | mm | ψ405x32~50xψ152.4(opt.ψ455x50~80xψ152.4) | ||

| Rotating speed of grinding wheel spindle | rpm | 1650(1890) | |||

| Maximum peripheral speed | m/sec | 35(45)m/sec | |||

|

Wheel head |

Feed angle | deg | GP=90,GA=60 | ||

| Maximum feed rate | mm | 6m/min | |||

| Minimum setting unit | mm | 0.001 | |||

| Total stroke | mm | 250 | |||

|

Head stock |

Spindle speed | rpm | 10~600 | ||

| Center taper | MT | MT4 | |||

| Spindle through hole diameter | mm | 25 | |||

|

Tailstock |

Sleeve stroke | mm | 30 | ||

| Center taper | MT | MT4 | |||

|

Worktable |

Swivel angle | deg | -8~+11 | -6~+9 | -4~+7 |

| Rapid traverse speed | mm | 6m/min | |||

| Minimum setting unit | mm | 0.001 | |||

|

Motor |

Grinding wheel spindle motor | hp | 5(7.5) | ||

| Head stock motor | kw | 1.0(1.5) | |||

| Hydraulic motor for grinding wheel spindle | hp | 1/8 | |||

| Coolant pump motor | hp | 1/4 | |||

| X-axis feed servo motor | kw | 1.0(1.2) | |||

| Z-axis feed servo motor | kw | 1.5(1.8) | 1.5(1.8) | 1.5(1.8) | |

|

Control system |

MITSUBISH(FANUC) | ||||

|

Net weight (approx.) |

kgs | 2600 | 3000 | 3400 | |

|

Gross weight (approx.) |

kgs | 2800 | 3200 | 3600 | |

|

Packing size(L*W*H) |

mm | 2400x1900x2000 | 2800x1900x2000 | 3200x1900x2000 | |

*We reserve the right to modify any machine specifications without prior notice.

| Standard accessories | ||

|---|---|---|

| Grinding wheel and flange * 1 set | Workpiece drive ring * 1 set | Standard water tank and pump |

| Grinding wheel dismounting device * 1 | Balancing stand and arbor * 1 set | Grinding wheel inverter |

| Diamond dresser * 1 set | MT4 center * 2 pieces | Gap elimination anti-collision device |

| Toolbox * 1 set | Heat exchanger in electric box | Quartz work lamp |

| Optional accessories | ||

|---|---|---|

| X-axis digital readout | Manual 3-jaw chuck | 2-point center rack |

| Z-axis digital readout | Oil mist collector | 3-point center rack |

| Outer diameter measuring device | Magnetic separator | Workpiece support rack |

| Automatic grinding wheel balancer | Paper filter | Grinding wheel suspending rack |

| Hydraulic tailstock | Air conditioner in electric box | Grinding wheel hanger |

| Manual 3-jaw chuck |