21YRS

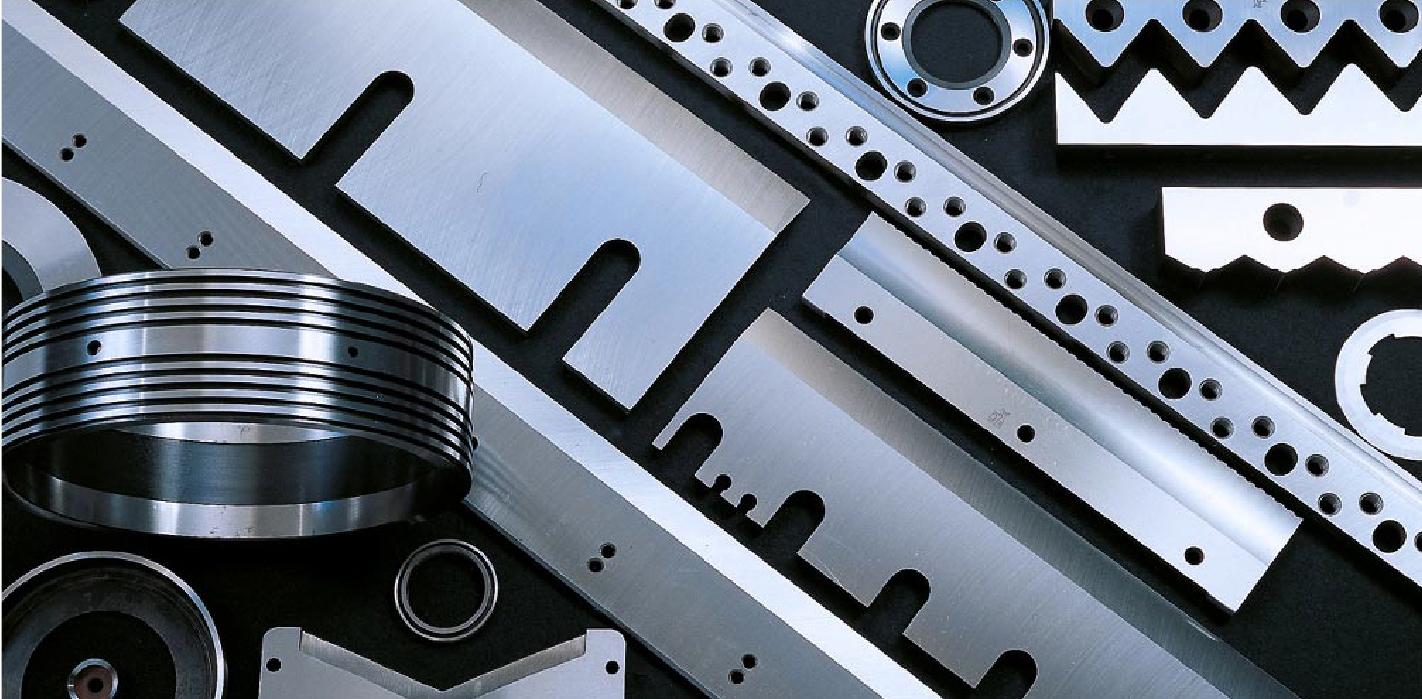

WU JII INDUSTRY CO., LTD.

Products

Specification

|

DIN material NO.:1.2379 ISO-B |

||||||

| Chemical composition |

C |

Cr |

Mo |

V |

Mn |

Si |

|

1.55 |

11.5 |

0.7 |

1.0 |

0.36 |

0.3 |

|

|

Steel properties : Ledeburitic-high-carbon high chromium steel. Highest wear-resistance, good toughness. Best edge-holding quality and retention to tempering; the steel can be nitrided after a special heat treatment. |

||||||

|

Applications : Thread rollings and thread rolling dies, cold extrusion tools, blanking and stamping tools, circular shear blades, deep drawing tools, pressure pads and highly wear-resistant plastic moulds. |

||||||

| Heat treatment |

Soft annealing | Cooling | Hardness | ||||||

| 830~860°C | Slow in the furnace | HB250max | |||||||

| Hardening | Cooling | Hardness after quenching | |||||||

| 1000~1050°C | 500~550°C oil or hot bath | HRC63 | |||||||

| Tempering°C |

100 |

200 |

300 |

400 |

500 |

525 |

550 |

600 |

|

| HRC |

63 |

61 |

58 |

58 |

58 |

60 |

56 |

50 |

|

| Special heat treatment |

Higher temperature hardening | Cooling | Hardness after quenching | ||||||

| 1050~1080°C | 500~550°C oil or hot bath | HRC61 | |||||||

| 3 rd tempering °C |

100 |

200 |

300 |

400 |

500 |

525 |

550 |

600 |

|

| HRC |

61 |

60 |

58 |

59 |

62 |

62 |

57 |

50 |

|