SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Products

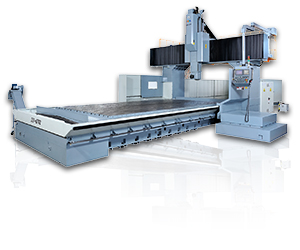

CNC Double Column 5-Face Machining Center

CNC Double Column 5-Face Machining Center (S5F)

S5F

► S5F- 3732 , S5F- 4732 , S5F- 4737 ,

S5F- 5732 , S5F- 5737 , S5F- 6737 ,

S5F- 5742 , S5F- 6742

Specification

| MODEL / ITEM | UNIT |

S5F-5737 / 6737

|

S5F-5742 / 6742

|

| X- AXIS TRAVEL | mm |

5700 / 6700

|

5700 / 6700

|

| Y- AXIS TRAVEL | mm |

3700

|

4200

|

| Z- AXIS TRAVEL | mm |

1000 ( 1200 )

|

|

| TABLE SIZE | mm |

5000x2700 / 6000x2700

|

5000x3200 / 6000x3200

|

| T SLOTS DIMENSION | mm |

22 ( 28 )

|

|

| TABLE LOAD CAPACITY | kgs |

20000 / 22500

|

22000 / 24000

|

| DISTANCE BETWEEN TWO COLUMNS | mm |

3000

|

3500

|

| DISTANCE FROM SPINDLE NOSE TO TABLE | mm |

V-150 ~ 1150 mm ( 150 ~ 1350 mm )

H-288 ~ 1288 mm ( 288 ~ 1488 mm ) |

|

| SPINDLE TAPERBTOOL SHANK |

|

ISO NO.50 BT-50BCAT-50BDIN 69871

|

|

| SPINDLE SPEED RANGE | rpm |

20 3000 TWO STEP GEAR BOX

|

|

| MAIN MOTOR OUTPUT (30 MIN RATING/CONT) | HP |

35 / 30

|

|

| RAPID TRAVERSE RATE X AXIS | mm/min |

8000

|

|

| RAPID TRAVERSE RATE Y , Z AXIS | mm/min |

10000 ( 12000 )

|

|

| CUTTING FEED RATE | mm/min |

1 5000 ( 1 8000 )

|

|

| MINIMUM INPUT INCREMENT | mm |

0.001

|

|

| TOOL MAGAZINE CAPACITY | pcs |

40 ( 60 / 80 / 120 )

|

|

| MAX. TOOL DIAMETERADJACENT POCKETS EMPTY | mm |

Ø125 / Ø250

|

|

| MAX. TOOL LENGTH (FROM GAUGE LINE) | mm |

V-400 / H-400

|

|

| MAX. TOOL WEIGH T | kgs |

20

|

|

| TOOL SELECTION METHOD |

|

ABS]Shortest Path^

|

|

| TOOL CHANGE TIME (T-T) | secs |

V-14 / H-20

|

|

| POWER REQUIREMENT | KVA |

65

|

|

| FLOOR SPACE REQUIREMENT | mm |

14400x7220 16400x7220

|

|

| MACHINE HEIGHT FROM FLOOR LEVEL | mm |

5100 ( 5500 )

|

|

| MACHINE WEIGHT (APPROX) | kgs |

61000 66000

|

|

| CNC CONTROLLER | Fa |

Fanuc, Siemens, Heidenhain, Series etc

|

|

| POSITIONING ACCURACY | mm |

JIS 6338 0.01/300, VDI 3441 P0.035

|

|

| REPEATABILITY ACCURACY | mm |

0.005

|

|

| STANDARD ACCESSORIES | |

| 1. HORIZONTAL SPINDLE 90° AUTO DIVIDE (4 POSITION) 2.40 ATC MAGAZINE FOR V AND H TOOL CHANGE 3.LUBRICATION SYSTEM 4.SEMI-SPLASH GUARD 5.SCREW-TYPE CHIP CONVEYOR 6.CHAIN-TYPE CHIP CONVEYOR 7.COOLANT EQUIPMENT 8.SPINDLE OIL COOLER 9.Z-AXIS HYDRAULIC BALANCE UNIT |

10.PNEUMATIC UNIT 11.AIR BLOW FOR CHIP 12.WORK LAMP 13.AUTO POWER-OFF 14.M.P.G 15.PROGRAM END & ALARM LAMP 16.RS-232 INTERFACE 17.LEVELING BLOCK AND BOLTS 18.TOOL KIT 19.MAINTENANCE AND OPERATION MANUAL> 20.INSPECTION LIST |

| OPTIONAL ACCESSORIES | |

| 1.AUXILIARY TABLE (BY ORDER SIZE) 2.NC (ROTARY TABLE, INDEX TABLE) 3.60,80,120 A.T.C MAGAZINE CAPACITY 4.AUTO TOOL LENGTH DIAMETER MEASUREMENT 5.AUTO TOUCH PROBE SYSTEMT 6.LINEAR SCALE FEEDBACK |

7.COOLANT THROUGH SPINDLE SYSTEM 8.COOLANT THROUGH TOOL SHANK DEVICE 9.COOLANT AUTO AIR MIST DEVICE 10.SPINDLE TRANSMISSION GEAR OIL MIST 11.HORIZONTAL SPINDLE AUTO DIVIDE (8,12,24,72 POSITION) |

Note:

1. ( ) Description is optional accessories.

2. To research and improve our company keeps the right of changing design and structure at any time, this

data is just for reference.