2022-10-04

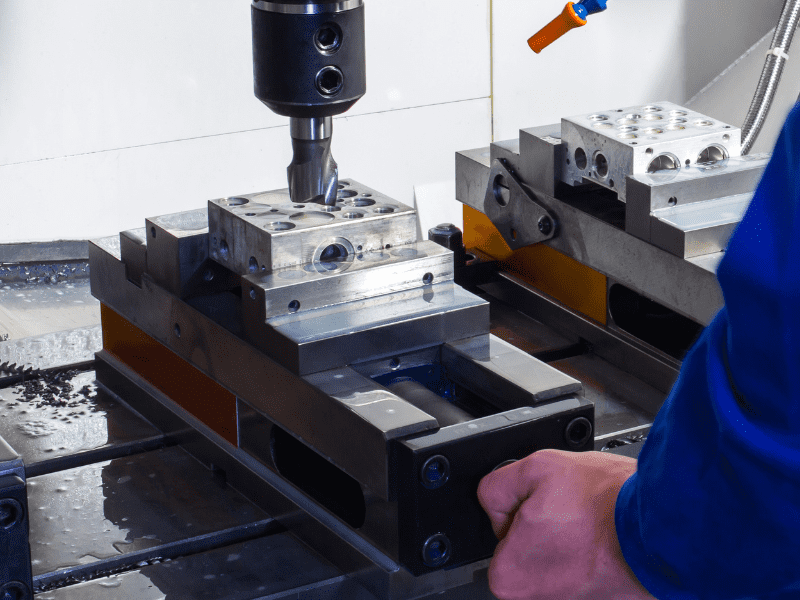

What is a Machinist Vise Used for?

An inventor's vise, also known as a machine vise, or colloquially, a "bench vise," is used to compress metal rather than clamping wood. Its primary function is to hold metal during the cutting and filing processes. The most common material is cast iron, but cast steel and malleable cast iron are also used.

An inventor's vise, also known as a machine vise, or colloquially, a "bench vise," is used to compress metal rather than clamping wood. Its primary function is to hold metal during the cutting and filing processes.

The most common material is cast iron, but cast steel and malleable cast iron are also used.

What is a machinist vise?

A clamp that has a wide base and two parallel iron jaws. metalworking vise means the same thing.

A machinist vise or bench vise. a clamp that is fastened to a workbench; it has two jaws to secure a workpiece.

What makes a good machinist vise?

A quality machinist vise will have a sturdy construction and will typically be made of cast iron. When the jaws are closed, the machine functions smoothly and reliably, and the work piece is lowered onto the bed via a wedge mechanism.

When the jaws are twisted, this prevents the part from being lifted because of deflection.

• Clean the table or tram the machinist vise:

Be sure to scrub the table of any chips that may be on it before having to put any grip on your machine table. It is important to avoid getting a chip stuck in the vise or on the table.

You will likely want to monorail the vise in addition to mounting it to a T-Slot table if you have one of those tables.

When trimming a grip, the lower lip of the vise is brushed with an index finger (you want the set jaw, not the moving jaw) to allow the position of the vise to be adjusted until the wave reveals that the upper lip of the vice is parallel to its axis. Set jaw, not movable jaw is what you're after.

• Vise parallels and jaw steps:

Supposing the vise has been installed and trimmed properly, the next question is how it should be used. Most of the time, we'll want the jaws to be fairly high up, so that the work piece can be held at a good height.

This is done for two reasons: first, so that the work piece can be accessed, and second so that the grip can become more secure and reliable as more of the work piece is secured. Simply put, when less of the work piece is gripped, there is less room for just a trip or other abnormalities to influence what is going on.

Although the Vise Jaw can be used for a wide variety of applications, one of the first things to keep in mind is that the jaws can be mounted either inside or outside the typical jaw mounting locations. When the jaws are mounted externally, the vise can hold a much larger workpiece than when they are mounted internally.

• Multiple vises, spanning jaws, and matching vises:

If you want to get the most out of your machine, you need to maximize the space provided by the table, as the adage goes. It is common practice to mount numerous vises on a milling machine's table, as most machine tables are large enough to support this.

The more vises you own, the more workpieces you can machine until having to stop the process so the controller can load new workpieces, so as long as your workspace can handle it, the more the merrier.

It's helpful if the machine's multiple vises are dimensionally consistent within a reasonable range of error. That way, it won't matter if the vises aren't in the same order when you're trying to replicate a setup.

• Double station Machinist vise:

Now that you have three to four vises spread across your factory table, you have effectively maximized the X-Axis. However, the Y-Axis could be utilized more effectively with double station vises:

Normal double station vises are like having two vises in one, as they can hold two pieces of work at once.

Getting a set of double vises is a good idea if you want to increase the number of parts you can work on at once on your mill's table.

• Vises to hold other workholding solutions:

Quite a bit can be accomplished with just vises, what with it by using various factors that play a part, double station vises, having to move the jaws approximately, as well as utilizing jaws that involve multiple vises.

The vises can also be used to secure other Workholding equipment. To reverse the jaws' direction of movement on a machinist's vise, all you have to do is place a sine vise inside of it.

• Quick change jaws:

I hope that you are starting to grasp the concept that Milling Vises to Personalized Jaws could be an effective method of work holding. For its efficacy, this Work holding type is used for a great deal of work.

The production of custom jaws takes a long time in shops, and once they are finished, the jaws are frequently boxed up and placed in storage so that they can be used for both these jobs or even in case a client needs to reorder a part.

FAQ:

Q: How do you use Machinist vise?

A: You will be able to use the machinist's vise to firmly hold items while you work on them once you have successfully attached them to the worktop in a secure manner. Put the piece of metal that needs to be worked into the vise by inserting it into the jaws of the vice grip.

Apply pressure to move it into the proper spot for the work that you want to do, and keep doing so until it is.

Q: What are vises made out of?

A: Vises for metalworking, woodworking and machines are typically constructed from a pair of materials. The vice's jaws, main body, and slide are typically placed from high-quality iron, whereas the vice's jaw edges, handle, and screw is cast from steel.

Q: What are examples of vises?

A: A moral failure or even a bad habit is referred to as a vice. Drinking, smoking tobacco, and engaging in risky gambling activities are three classic examples of the vise.

Contact HERBERT today for more informaiton!

HER BERT ENTERPRISE CO., LTD.

TEL : 886-4-26275073

FAX : 886-4-26271395

No. 40, Lane 157, Min You Rd., Chine Shui, Taichung 436, Taiwan