2022-06-06

A Guide About Pros and Cons of Die Casting

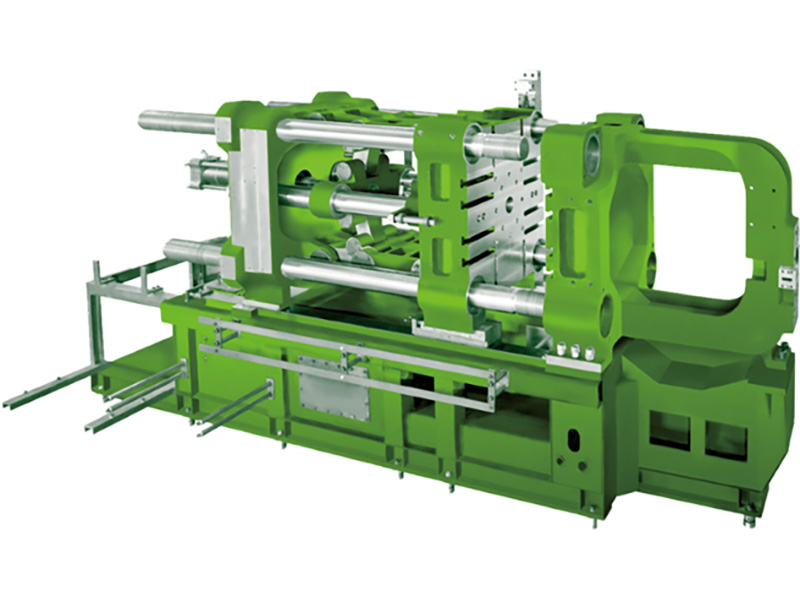

From engines blocks and cylinder heads to bikes and other garden furnishings, die-casting has been employed to make numerous items. Die-casting is one of the most inventive and versatile processes used for casting metal. In this method, a mold cavity is used to create the object. Then, high tension is applied to the melting metal that fills the cavity. The raw material is heated and then pushed into the mold. When the molten material is cooled down and has hardened, a new casting is created.

Thanks to its distinct characteristics, die-casted components are precise to cast. While die-casting is believed to be a very versatile casting process, however, it comes with distinct advantages and disadvantages that we will try to explore in this article. While we are at it, we will also compare it with other manufacturing methods.

Die Casting Pros

Die casting can be used with a variety of alloys and metals. Zinc is the most popular option for this process due to its high flexibility as well as its strength. It's also quite affordable and is therefore ideal for large-scale manufacturing. Other alloys and metals supported by die casting include copper, aluminum, magnesium, lead, and Tin.

When using die casting machine, manufacturing companies don't need to fret about hard or sloppy casting surfaces. Because it uses pressurized melting of metal, it can create smooth surfaces for castings. Since the molten metal has been placed into the mold cavity, it fills in the space for a smooth and smooth surface.

Another advantage of the die casting auto sprayer is its capacity to cut down the need to finish operations. In other casting procedures, castings are typically done with the aid of a machine. These machining procedures can be lengthy and time-consuming. However, the good news is die casting eliminates the necessity for such processes. In many cases, auto extractor is ready for shipping after the casting process has been completed.

Die-casting offers an array of different alloys and metals you can choose from. A few well-known options for this casting method are zinc due to its strength and elasticity. However, die-casting is affordable, making it ideal for manufacturing large-scale. Other metals and alloys that could be used for die-casting include aluminum lead as well as copper, Tin, and magnesium.

Die Casting Cons

However, die casting can be costly when compared with other casting techniques. It requires a specific casting machine that is costly to buy and maintain. Companies that manufacture can save money by using zinc as the casting material; however, aluminium casting machine remains an expensive process.

Die castings also have weight limits to which castings have to adhere. For example, a typical casting could need a weight of one up to 15 pounds. It is an issue if the casting weighs less or more than the recommended weight.

Conclusion

To summarize the basics, densification is the process used in manufacturing industries to produce objects made of pressurized molten steel. The metal, or alloy, in this case, is heated then pressed into a mold. As the molten material is cooling, it begins to harden. The cast that has solidified can take off from its mold.

EVERGREAT MACHINERY CO., LTD.

TEL : 886-6-2725358

FAX : 886-6-2714009

No.76, Ln. 48, Nanxing Rd., Yongkang City, Tainan County 710, Taiwan