2022-01-17

Single vs. Dual Pneumatic Cylinder - What’s the Difference?

Single vs. Dual Pneumatic Cylinder - What’s the Difference?

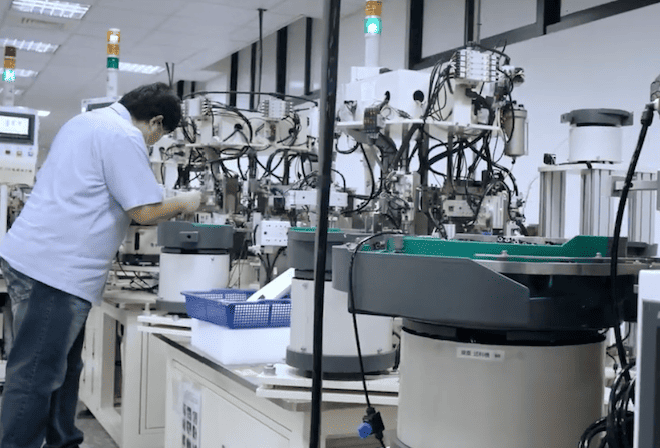

Do you need devices that can perform continuous movements with no need for you to push any buttons? Most of today’s business sectors, including packaging, factory automation, automotive manufacturing, and transportation, integrate pneumatic components into the designs of their machines. These pneumatic systems are clean, inexpensive, and reliable.

What are Pneumatic Cylinders?

A pneumatic cylinder, or also called an air cylinder or actuator, is a mechanical device that uses compressed air for moving a load in a linear path. The most usual kind of pneumatic actuator features a piston and a rod that moves within the closed cylinder in which the piston carries out the preferred movement. Pneumatic systems use air as an energy source for operating and completing a specific task, which is to extend and retract the piston within the cylinder in this case.

Pneumatic cylinders are often applied as two primary types of pneumatic cylinders – the single and dual pneumatic cylinders.

The specific number of ports is the primary difference in the design of these two cylinders. A single pneumatic cylinder has a single port where the pressurized air will enter. A dual pneumatic cylinder, on the other hand, uses two ports for its operation.

This rather simple difference in designs sets these two cylinders apart when it comes to speed and movement. Take a look at a quick overview of these two types of pneumatic cylinders:

What is a Dual Pneumatic Cylinder?

If you need a device that moves loads in both directions, you can use a dual pneumatic cylinder. This is a useful application if your machine needs more than a single movement. Dual pneumatic cylinders, unlike their single counterparts, can retract and extend with no need for a spring. A dual pneumatic cylinder has two ports that allow air to enter and exit rather than applying the pressurized air into a single port alone.

The air will enter through the first port to move the piston forward and apply pressurized air to the second port to retract back the piston into the cylinder. Dual pneumatic cylinders are currently the most commonly used pneumatic actuators, more so than single pneumatic cylinders. This is because of their ability to retract and extend within a faster timeframe, making them more precise and efficient.

Dual pneumatic cylinders are typically used in robotics and industrial industries. These can perform tasks like closing or opening doors as well as moving and lifting off merchandise from conveyor belts. Earth-moving equipment, medical applications, and space programs are other fields where dual pneumatic cylinders are most applicable.

Single Pneumatic Cylinder

The single pneumatic cylinder is your best option if you need to use your machine in linear motions and carry out movements like punching, positioning, and clamping. How do these pneumatic cylinders work? A single pneumatic cylinder has a single port in which pressurized air will enter in just one direction. The load or spring is often fitted into the piston. When the air is compressed and cleaned, this will enter through one port that forces the piston to extend in a single direction to compress the spring.

TAIWAN CHELIC CO., LTD.

TEL : 886-2-29041235

FAX : 886-2-29068203

No.21, Guifeng St., Taishan Dist., New Taipei City 243, Taiwan