2021-12-23

What are the benefits of a 2-axis milling head

Manufacturing industry is something that continues to evolve along with time. We can also see multiple innovations popping up on a regular basis. In order to keep up with the changing world, manufacturers have come up with the need to use machines, which they can use to produce products efficiently and faster. Moreover, they also come across the need to reduce the number of errors that they make. This is the main reason why they take a look at multi-axis milling heads. As you take a look at multi-axis milling heads, 2-axis milling head is the very first thing that will come to your mind. Continue to read and we will share all benefits that you can get out of them.

- You can end up with getting a better surface finish

A shorter cutting tool may be used on a 2-axis machine. As a consequence, there are less vibrations at extremely high speeds. As a result, higher surface finishes are achieved. Using the machine's fourth and fifth axes, you may do this. The component may then be oriented and brought considerably closer to the cutting tool. The closer the component is to the cutting tool, it will be shorter, which minimizes vibrations greatly. If you already have outstanding surface finishes on the component, you may save a lot of time hand-finishing it.

- You may improve the overall tool lifespan

2-axis machining may actually extend the life of a tool. It improves as a consequence of the instrument or table being titled on a regular basis. This is done to keep the cutting position as optimal as possible.

- You can effectively improve relational accuracy

2-axis machining provides greater relational precision since it requires fewer setups. You increase your chances of suffering imprecision every time you relocate a component for re-fixturing or a configuration modification. This is because if you shift one section of the machine, the perfect alignment would be lost. Relational correctness will be greatly improved by having fewer setups and utilizing the same "home" or "zero" position.

- You can expect to receive a quick turnaround

Fewer setups are required for a quick turnaround. In comparison to its predecessors, CNC machining requires substantially less setup. Every visible surface may be machined using 2-axis machining, with the exception of the clamping or bottom areas. This characteristic implies that it may be used without the need of several specific fixtures or extra setups. This may sometimes decrease the number of setups required to just one. This saves a lot of time, effort, and aggravation.

- You have the ability to manufacture complex shapes with ease

The capacity to generate complex 3D things is one of the most well-known and significant benefits of 2-axis machines over 3-axis machines. Because of the extra motions it can do, it is able to create a variety of arcs and angles. Previously, these moves could only be performed with the help of a number of clumsy setups and unique fittings on the machine. This also makes prototyping and small-run product production considerably quicker and less expensive, which saves a lot of time.

Final words

As the manufacturing industry continues to grow, we will be able to see 2-axis milling heads gaining more attention along with time. The benefits we shared above are the main reason behind their popularity. You can see how multiple industries out there, including small businesses have been able to receive maximum benefits that come along with the 2-axis milling heads.

Milling Machine Head

The milling head is the most important component of the milling machine accessory. The milling head is divided into 4 series: CNC Milling Head, Gantry Milling Head (Plano Milling Head), Turret Milling Head (Bridgeport Milling Head), and Angle head. It is installed on the milling machine and connected with the spindle to drive the milling cutter to rotate.

-

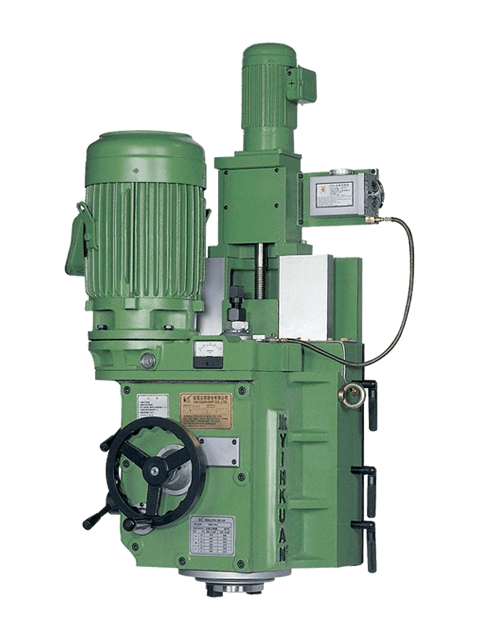

Gantry Milling Head (Plano Milling Head)

The milling heads are commonly used milling machine heads such as gantry milling machines, boring milling machines, and double-head milling machines.

VIEW MORE -

CNC Milling Head

The milling head is commonly used milling machine heads such as computer gantry milling machine, machining center milling machine and so on.

VIEW MORE -

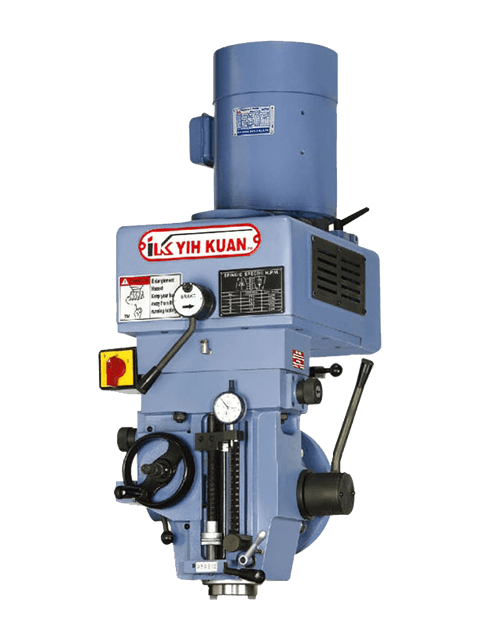

Turret Milling Head (Bridgeport Milling Head)

The milling heads are commonly used milling machine heads such as turret milling machines, bed milling machines, and vertical and horizontal milling machines.

VIEW MORE -

GREEN ECO PRO CO., LTD.

TEL : 886-4-25350511

FAX : 886-4-25350322

No.12-19, Ln. 183, Sec. 4, Chongde Rd., Tanzi Dist., Taichung City 42755, Taiwan