2021-12-16

What is the difference between CNC drilling machines and CNC milling machines?

People often tend to figure out the difference between CNC drilling machines and CNC milling machines. As a result, they tend to make incorrect purchases. If you don’t want to end up with such a situation, it is extremely important to have a good overall understanding about the differences between them. Continue to read, and we will share some of the most prominent differences that you can find in between a CNC drilling machine and a CNC milling machine.

What is a CNC drilling machine?

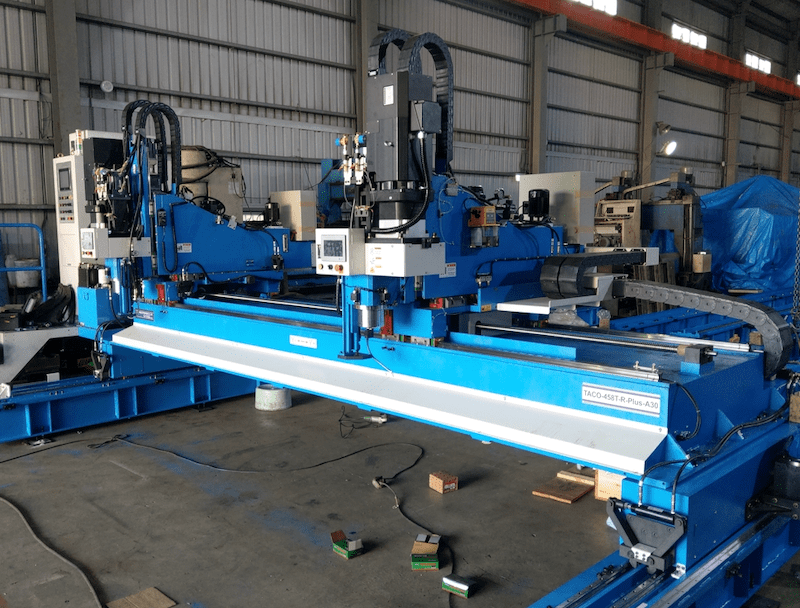

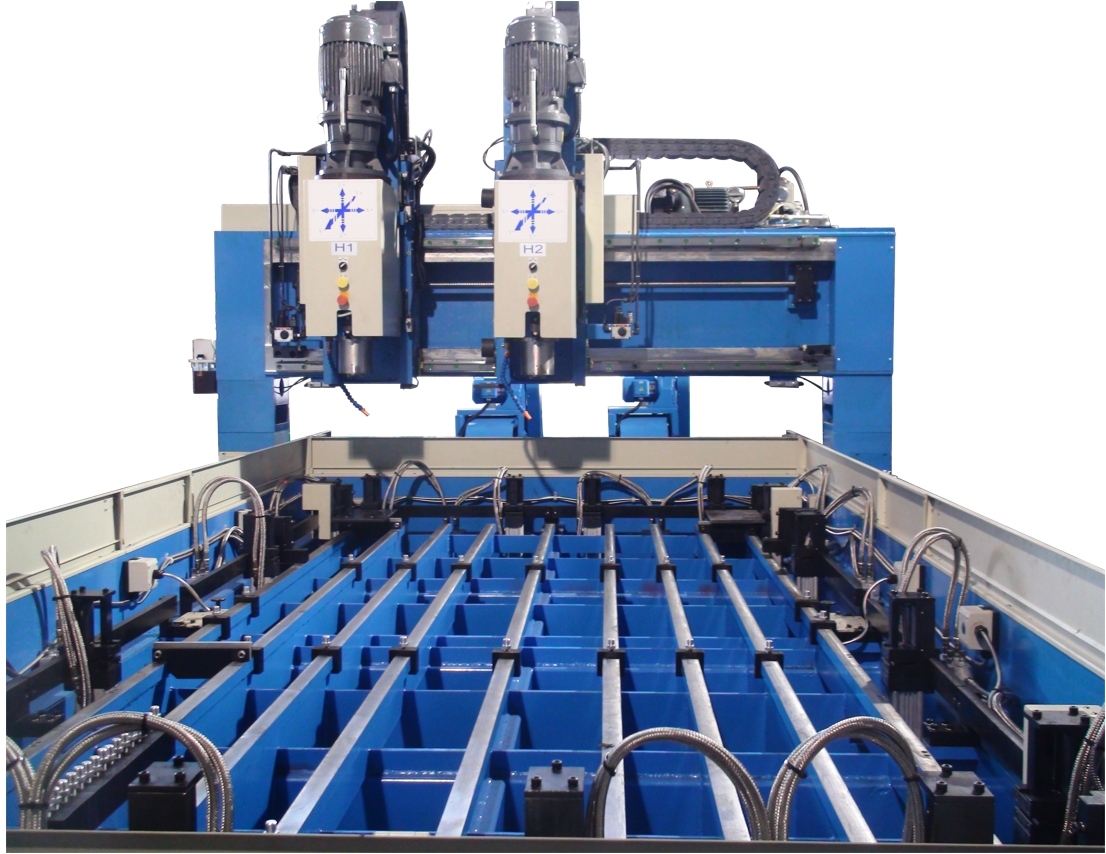

A CNC drilling machine would come along with a fixed drill. You will be able to mount this drill on top of a stand. Or else, you may even bolt the drill on a workbench or the floor. You have the ability to change the speed of the drilling machine. All you have to do is to manually move the belt through the pulley arrangement available.

You can expect to receive multiple benefits out of a plate drilling machine. Out of them, you can’t simply ignore the mechanical advantage that you will be getting. The drilling machine is fixed into a table. Due to the same reason, it is possible to use a clamp or a vice to secure and position the workpiece effectively. This would make the overall operation of the CNC drilling machine highly accurate. On the other hand, you will also notice that the spindle angle coming along with the machine is fixed in relative to your table. Therefore, you can continue to drill holes in repeated movement. On top of that, you will also be able to ensure the accuracy of the holes that you are drilling.

Drilling machines were out there for quite some time. The traditional drilling machines were taken to the next level along with automation technologies. Hence, you shouldn’t worry too much about anything as you invest your money to buy a CNC drilling machine. You will be able to program the CNC drilling machine, so that you can end up with getting precise results at the end of the day.

The CNC drilling machines are quite effective at the time of drilling pattern holes. On the other hand, they can also benefit you when you are drilling angled holes and small holes. However, we can also see how people are frequently using these drilling machines to work on random workshop activities. Some of the most prominent activities out of them include polishing, honing, and sanding. You may also use them to work on multiple rotating accessories.

What is a CNC milling machine?

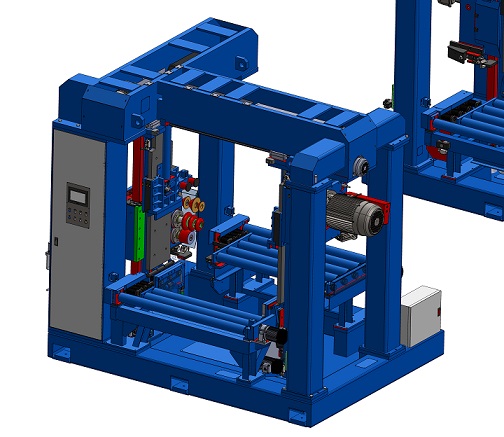

CNC milling machines are quite different from the drilling machines. That’s because you will be using a milling machine for the purpose of reshaping a metal or any other solid object. It is possible for you to get CNC milling machines in two different varieties. They include vertical CNC milling machines and horizontal CNC milling machines. This would refer to the exact position of the spindle cutting tool.

One of the biggest differences that you can see in a CNC milling machine is that they don’t keep the workpiece stationary. They will also make sure that the workpiece is moving. This is required to get the expected functionality at the end of the day.

You will be able to find advanced CNC milling machines available out there as well. They are in a position to deliver a high level of flexibility for the people who use them. You may think about using this kind of a machine for hand-engraving tasks.

Products

Plate Drilling Machine

Rail Type Bridge Plate Drilling Machine

Beam Line Drilling Machine

Laser Marking Machine

- H-Beam Bevelling machine

Products - Plate Drilling Machine

- Rail Type Bridge Plate Drilling Machine

- Beam Line Drilling Machine

- Laser Marking Machine

- Beam line stamper

- H-Beam Scallop & Beveling machine

- Plate beveling machine

- Auto Arm Welder

- Pipe Notcher

- Drill Grinder

- Magnetic Core Drilling Machine

- Remolift

- Shear Wrench

- H-Beam Rotater

TRINKLE ENTERPRISE CO., LTD.

TEL : 886-4-23581123

FAX : 886-4-23581138

No.8, Gongyequ 31st Rd., Xitun Dist., Taichung City 407, Taiwan