2021-12-14

What is EDM Machine, and how it works?

What exactly is an EDM machine?

A metal production method in which the desired form is created by employing electrical discharges is called electrical discharge machining (EDM machine).

Working of EDM Machine

When a succession of fast recurring current discharges between the two electrodes that are separated by a dielectric liquid and subjected to an electric voltage occurs, the material is taken from the workpiece.

Depending on the electrode, one is referred to as the tool-electrode, simply the tool or electrode, while the other is referred to as the workpiece-electrode or just the workpiece. The technique is dependent on the fact that the tool and the work item do not come into physical touch.

When the voltage between two electrodes increases, the power of the electric field in the volume between the electrodes increases, causing the dielectric breakdown of the liquid and the formation of an electric arc.

When the voltage between two electrodes decreases, the power of the electric field in the volume between the electrodes decreases. This causes the material to be removed from the electrodes due to the process. For the current to cease to flow, the new liquid dielectric is introduced into the inter-electrode volume, allowing the solid particles to be transported away and for the insulating properties of the dielectric to be restored.

Flushing is the term used to introduce fresh liquid dielectric into the inter-electrode volume. A current flow restores the voltage between the electrodes to its pre-breakdown state, allowing a fresh liquid dielectric breakdown to occur, thus repeating the cycle.

Types of EDM:

Electrical discharge machining (EDM) is divided into three categories:

- Sinker EDM

- Wire EDM

- Hole drilling EDM

It is possible to use electrical discharge machining in three distinct ways.

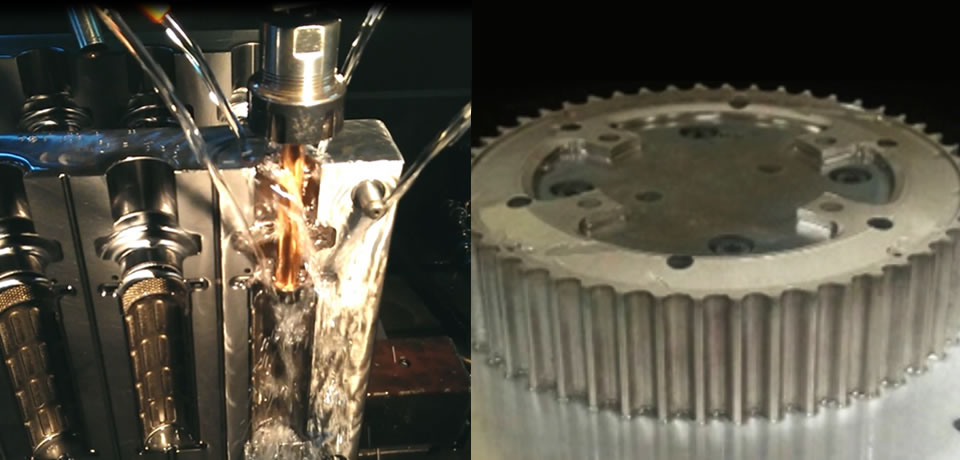

Sinker EDM Machine

Sinker EDM machine is the term used to describe the process outlined above. Die sinking, cavity type EDM, volume EDM, classic EDM, and Ram EDM machine are used to describe this process. Die sink EDM enables users to create complicated forms with a single tool.

Sinker EDM machines of the CMAX S1470 type are advanced CNC machines. It comes with motion machining in 3D mode. The oil tank has a capacity of 2080 liters. The machine's body is built of cast iron and can support loads of up to 6000 kg. THE OPTIONAL ELECTRODE HEADS OF the C, A and B axes may control the six axes. It may also be attached to a robot hand, allowing it to alter the electrodes. The work table measures 1850 x 1000 mm and is mostly utilized in aerospace manufacturing.

This approach necessitates using electrodes (typically composed of graphite or copper) that have been pre-machined to the precise form required. The electrode is subsequently sunk into the workpiece, resulting in the creation of the negative counterpart of the original form of the workpiece.

Wire EDM

Wire EDM (Electrical Discharge Machining) is a second form of electrical discharge machining that is sometimes referred to as wire erosion, wire burning or spark EDM. A thin wire is utilized to cut through the material to cut the workpiece in Wire EDM.

It is the wire in this scenario that serves as the electrode. Wire is continuously fed into the machine via an automatic feed using a spool throughout the machining process. If the cut has to be made in the center of the workpiece rather than on the outside, a tiny hole drilling EDM is used to create a hole in the workpiece through which the wire may be threaded once it has been formed the middle.

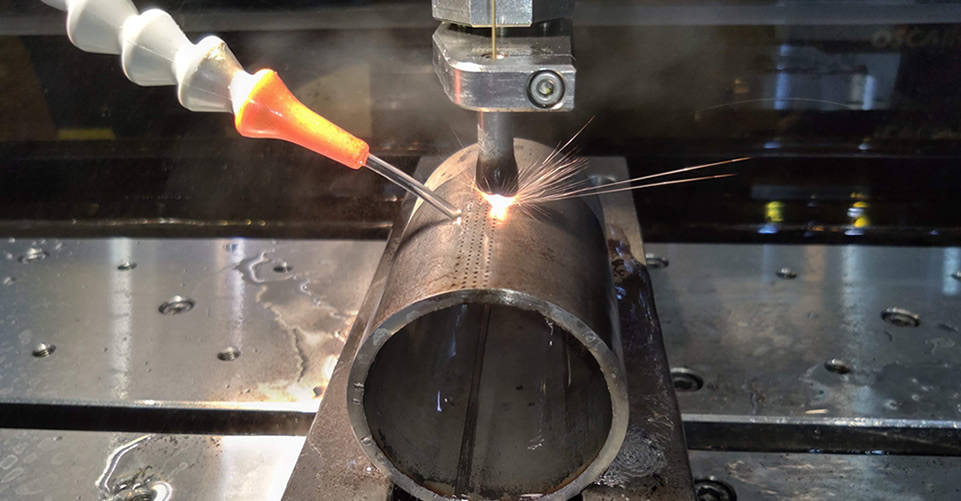

Hole drilling EDM

The last form of electrical discharge machining is hole drilling EDM, which stands for electrical discharge machining. This procedure is utilized for drilling holes, as the name implies. EDM can machining exceedingly tiny and deep holes with greater precision compared to typical drilling processes.

In addition, EDM drilled holes do not need any deburring to be completed. The electrodes used in this method are tubular, and the dielectric fluid is supplied into the electrode from inside the electrode.

OSCAR E.D.M. COMPANY LTD.

TEL : 886-4-23385818

FAX : 886-4-23380035

No.359, Xuetian Rd., Wuri Dist., Taichung City 414, Taiwan