Products

Features of UNION TOOL Dills

UNION TOOL recommend drill models based on actual drilling data depending on customer's conditions, to correspond to a great variety of PCB material characteristics and drilling parameters. For example, even the drills of same size, is classified into following 3 types according to the drill design, where drill selection enables to respond to customer's quality target.

Hole Registration Accuracy Type

The drill is especially designed considering the rigidity. It enables to maintain an excellent hole registration accuracy in the drilling process.

Hole Wall Roughness Type

The drill is designed especially considering the chip evacuation. Enables to maintain a good hole wall quality while drilling.

Balance Type

The drill is designed considering the rigidity and the chip evacuation. It offers a good balance with hole registration and inner hole wall quality during the drilling process.

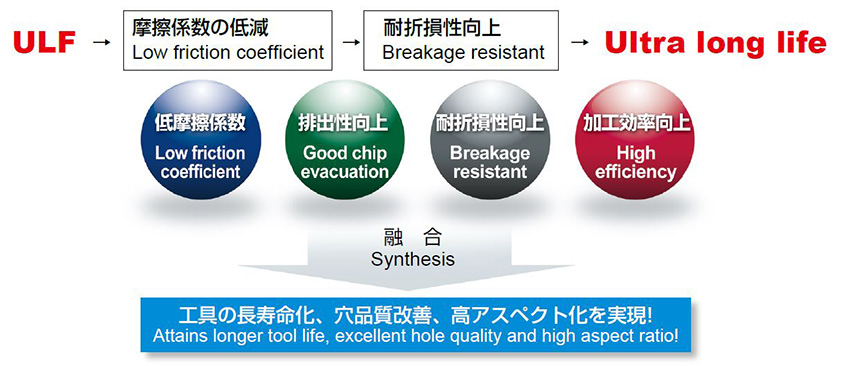

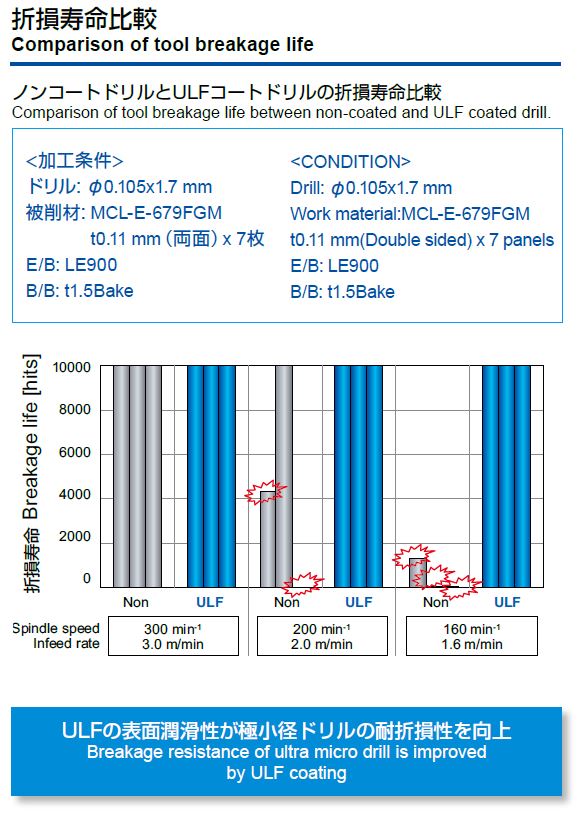

Furthermore, together with geometry and material development, and applying ULF coating which is developed and optimized for PCB drilling, enables to drill holes in PCBs that were difficult to drill with conventional drills.

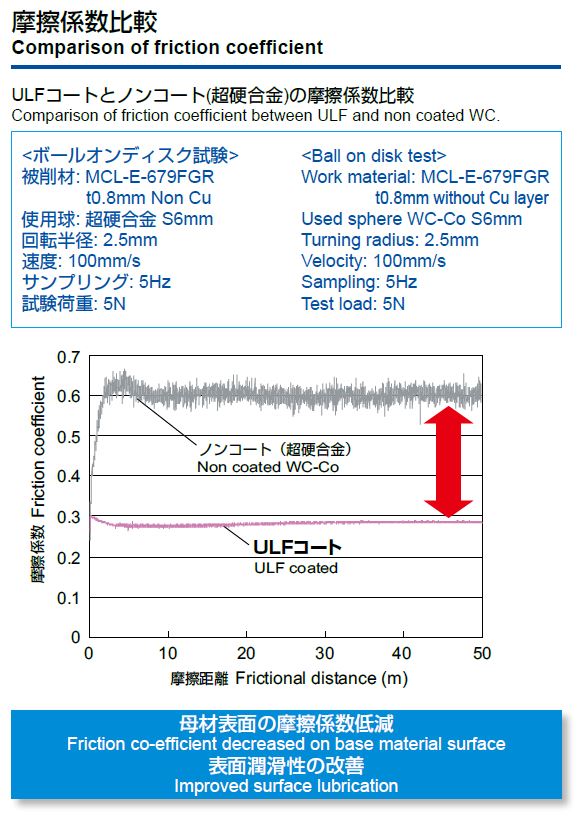

Features of ULF Coating

ULF (Uniontool Lubricant Film) coating features low friction coefficient.

We will develop drill bit geometry considering with the characteristic of ULF to meet further long life and stack up requests.

Technical data

ULF coated router RPEMU

RP20(Conventional)

RPEM(New)

*This is a picture of Non-coated routers.

FR-4 Spot facing

| Work | R-1566 t1.6mm x 1panel/stack(Halogen free, No copper) |

|---|---|

| Conditions | N = 25krpm, Fxy = 0.8m/min, Pocket depth = 0.5mm |

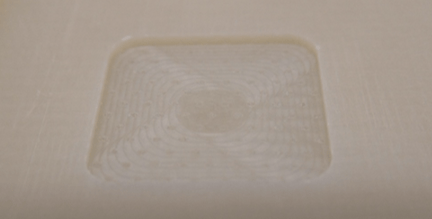

φ3.0 Non-coated(after 2m)

Conventional

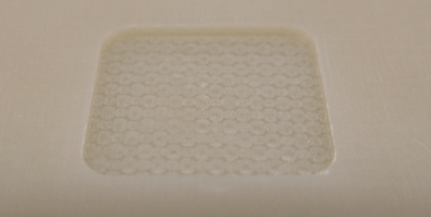

RPEM

Due to optimized cutting edges of RPEM, cutting-mark on bottom surface will be controlled.

Copper Spot facing

| Work | C1020P t1.0mm x 1panel/stack |

|---|---|

| Conditions | N = 35krpm, Fxy = 0.4m/min, Pocket depth = 0.5mm |

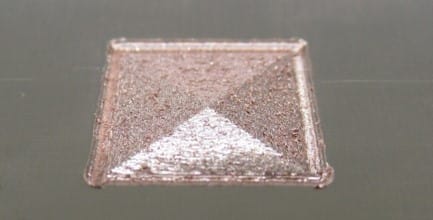

φ1.0 ULF coated(after 10m)

Conventional

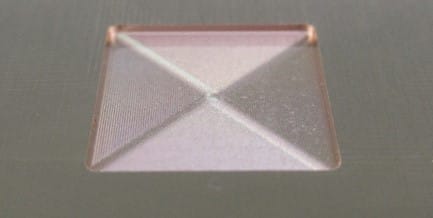

RPEM

With ULF coated RPEM, less burr and smoother surface can be possible.