SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Products

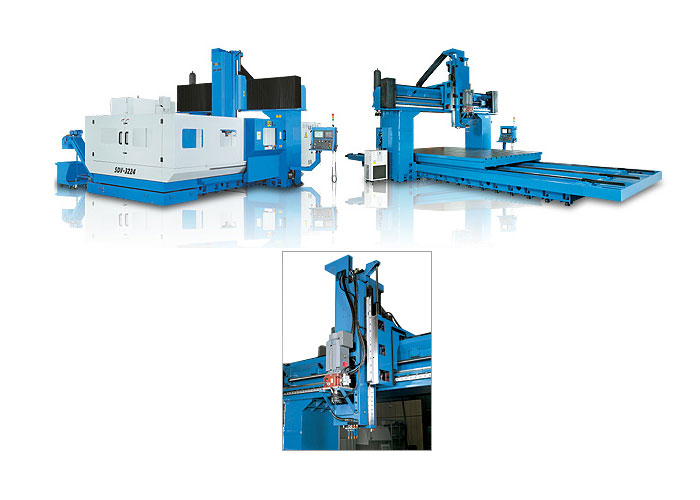

CNC gantry type machining center machinesCNC Double Column M

CNC Double Column Machining Center (SDV)

SDV

| ► SDV - 1611, SDV - 2011 |

| ► SDV - 2215, SDV - 2219, SDV - 3215 |

| ► SDV - 3219, SDV - 3224 |

| ► SDV - 4219, SDV - 4224 |

| ► SDV - 5224, SDV - 5229 |

Specification

| Item / Model | Unit | SDV 1611 | SDV 2011 |

| X-Axis Travel | mm | 1,600 | 2,040 |

| Y-Axis Travel | mm | 1,100 | |

| Z-Axis Travel | mm | 760(1,000) | |

| Table Size | mm | 1,600x1,000 | 2,000x1,000 |

| T-Slots Dimension | mm | 22(24,28) | |

| Table Load Capacity | kgs | 3,000 | 3,500 |

| Distance Between Columns | mm | 1,200 | |

| Distance From Spindle Nose To Table | mm | 250~1,010 (250~1,250) / 355~1, 115 (355~1,355) | |

| Spindle Taper Tool Shank | ISO No.50(40) BT-50,CAT-50B DIN 69871 (BT-40,.CAT-40) | ||

| Spindle Speed Range | rpm | 20~4,000(30~6,000)(100~10,000)(80~8,000) | |

| Main Motor Output (30 Min Rating/Cont) | HP | 25 / 20 (30 / 25) | |

| Rapid Traverse Rate X,Y-Axis | mm/min |

15,000(20,000) |

|

| Rapid Traverse Rate Z-Axis | mm/min | 12,000(15,000) | |

| Cutting Feed Rate | mm/min | 1~5,000(1~8,000) | |

| Minimum Input Increment | mm/min | 0.001 | |

| Tool Magazine Capacity | pcs | (16 / 20 / 32 / 40) | |

| Max.Tool Diameter /Adjacent Pockets Empty | mm | Ø125 / Ø210 | |

| Max. Tool Length (From Gauge Line) | mm | 350 | |

| Max. Tool Weight | kgs | (18 / 20) | |

| Tool Selection Method | (ABS,Random Bi) | ||

| Tool Change Time (T-T) (Approx) | secs | 8(4.5) | |

| Power Requirement | Kva | 40(45) | |

| Floor Space Requirement | mm | 7,200x4,800 | 8,000x4,800 |

| Machine Height From Floor Level | mm |

4,350 |

|

| Machine Weight (Approx) | kgs | 18,500 | 19,000 |

| CNC Controller | Fanuc,Meldas,Siemens, Heidenhain series etc. | ||

| Positioning Accuracy | mm | JIS B6338 0.01/300, VDI 3441 P0.025 | |

| Repeatability Accuracy | mm | ±0.003 | |

| STANDARD ACCESSORIES | |

| 1. LUBRICATION SYSTEM 2.GLAZED WINDOW-TYPE SPLASH GUARD 3.SCREW-TYPE CHIP CONVEYOR 4.LINK-TYPE CHIP CONVEYOR 5.COOLANT EQUIPMENT 6.SPINDLE OIL COOLER 7.Z-AXIS HYDRAULIC BALANCE UNIT 8.PNEUMATIC UNIT 9.AIR BLOW FOR CHIP(BY M-CODE) |

10.WORK LAMP 11.AUTO POWER-OFF 12.M.P.G 13.PROGRAM END & ALARM LAMP 14.RS-232 INTERFACE 15.LEVELING BLOCKS AND BOLTS 16.TOOL KIT 17.MAINTENANCE AND OPERATION MANUAL 18.INSPECTION LIST |

| OPTIONAL ACCESSORIES | |

| 1.AUXILIARY TABLE 2.NC(ROTARY TABLE,INDEX TABLE) 3.16, 20, 32, 40, 60, A.T.C MAGAZINE CAPACITY 4.TOOL PRESETTER 5.AUTO TOOL LENGTH DIAMETER MEASUREMENT 6.AUTO TOUCH PROBE SYSTEM 7.LINEAR SCALE FEEDBACK 8.COOLANT THROUGH SPINDLE SYSTEM |

9.OIL HOLE TOOL SHANK DEVICE 10.COOLANT AUTO AIR MIST DEVICE 11.COOLANT NOZZLE ANGLE REMOTE CONTROL 12.MANUAL 45°, 90° ANGLE HEAD, UNIVERSAL HEAD, EXTENSION HEAD 13.SPINDLE THERMAIL COMPENSATION 14.AVAILABLE WITH DIFFERENT SPINDLE SPEC & RPM 15.(AAC) 90° ANGLE HEAD, SWING DIVIDED ANGLE HEAD INDEX IN C-AXIS (AVAILABLE 4, 8, 12, 24, 72 POSITION), EXTENSION HEAD (360, 560 MM)(FOR SDV-H SERIES ONLY) 16.MANUAL FULL SPLASH GUARD |

Note:

1.( )Description is optional accessories.

2.To research and improve our company keep the right of changing design and structure at

any time, this data is just for reference