2021-12-13

Slitting Machine and Its Function

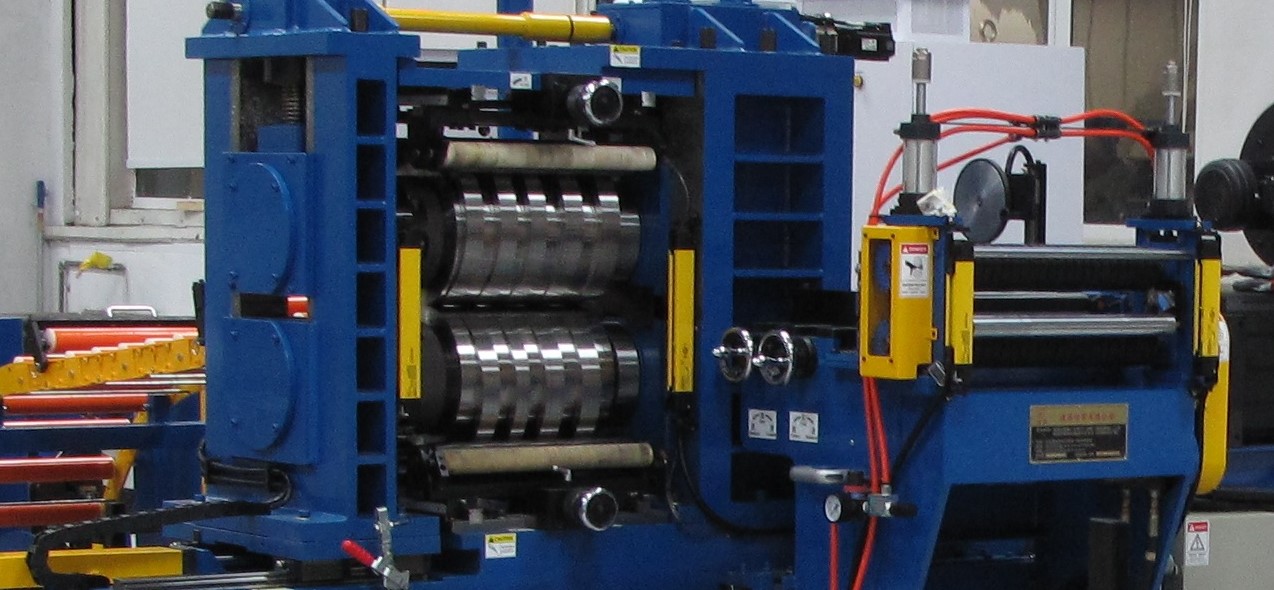

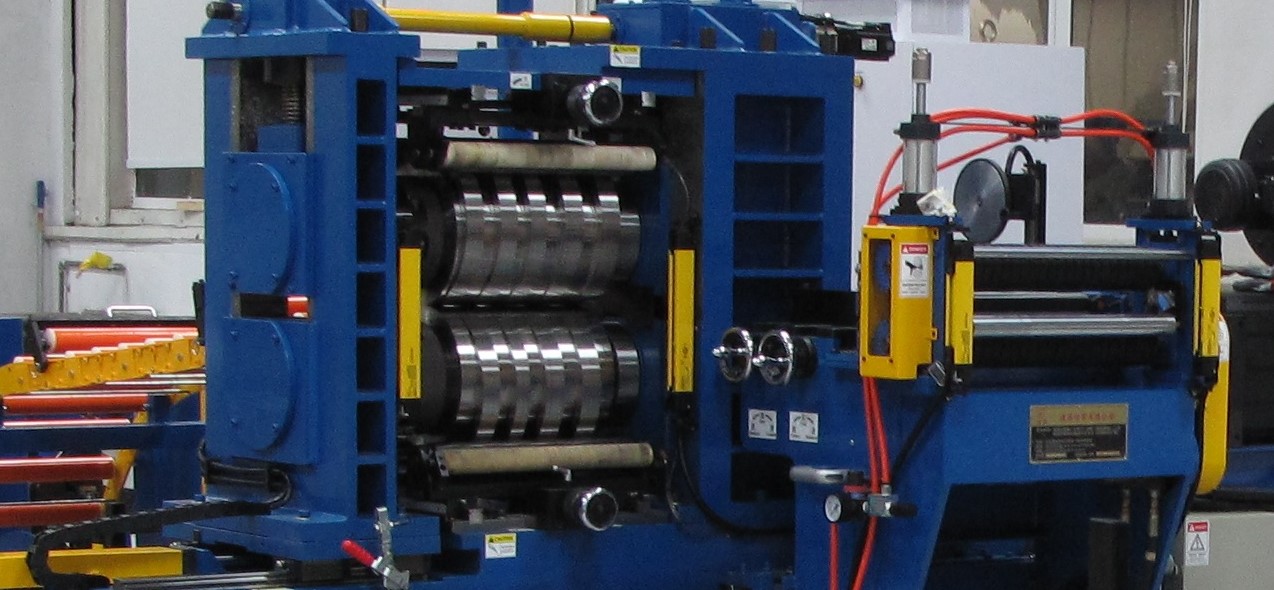

The specific machine that is used for the purpose of roll slitting is known as the slitting machine, a slitter, or a slitter rewinder. These different names can be used interchangeably when referring to the same machines.

Also referred to as rewind slitting or log slitting, roll slitting is a type of shearing operation that can cut large rolls of materials into narrower coils. The term log slitting is in reference to those days in the past when saw mills were used for cutting huge log pieces into smaller chunks. These saw mills were also used for cutting bigger iron rods to relatively smaller sections.

In the modern-day definition, the term slitting refers to the process wherein a coil of material gets cut down into several smaller coils with narrower measurements. The potential workpieces are noticeably thin measuring only at 0.001 up to 0.215 inch. These can also be machined in the form of sheets or rolls.

The process of slitting is regarded as a more practical alternative to other similar methods thanks to the versatility of the materials that it can manage as well as its high productivity. The process of rewind slitting is where the material goes through rewinding through the series of knives to produce narrower rolls of the materials.

Slitting machine is the term used when referring to the machine, and its three parts are called the rewind, the slitting section, and the unwind. The slitter rewinders are often used for slitting plastic films, metal foils, and paper.

The unwind is usually braked to retain the material’s accurate tension. There are also machines that feature a driven unwind that helps lessen the effect of inertia when the heavy rolls start to unwind or if the material is extremely sensitive to tension.

There are three primary options in the slitting section, namely crush cut slitting, rotary shear slitting, and razor slitting that is recommended for thin plastic film. There are also options in the rewind section. The primary type is the center winding that uses the differential rewind shafts.

The converters industry heavily uses the roll slitting technique. Most of the time, the converter industry pertains to those companies that print, laminate, and coat materials. The typical converters are the companies that manufacture or produce flexible packaging materials used to package food. It may involve buying large plastic film rolls such as BOPP or biaxially orientated polypropylene that is then printed to the design of the customer before being coated with the cold seal adhesive that is used on the high-speed packaging machine.

The material will then be coated and printed in large and wide diameter rolls for optimum efficiency. These rolls will then undergo slitting with the use of the slitting machine to convert them into smaller rolls in the specific size that will be used on the machine for packaging.

With the different functions of the slitting machine, it is easy to see the important roles it plays in different industries, making them a must-have tool today.