22YRS

伍全企業股份有限公司

STAMPINGMASTERS ENTERPRISE CO., LTD.

STAMPINGMASTERS ENTERPRISE CO., LTD.

產品介紹

- 伍全企業股份有限公司

- 產品介紹

- 平墊片/華司

- 模具墊片(材質:SK5)

- CBB-內六角螺絲(材質:SCM435+染黑)

- CAP-CBB-內六角螺絲(材質:SCM435+染黑\盒裝)

- SCBB ASCBB-內六角螺絲(材質:SUS304)

- CAP-SCBB-內六角螺絲(材質:SUS304\盒裝)

- EBS EBSH EBSST-低頭內六角螺絲(材質:S45C/SCM435/SUS304)

- EBSS EBSM EBSTS-極低頭內六角螺絲(材質:SCM435/SUS304)

- SMA222 SMA223 SMA224-超極低頭星型螺絲(材質:鋼/SUS304)

- RCBB RSCBB-外六角螺栓(材質:SCM435/SUS304)

- BCBB SBCBB-半圓頭內六角螺絲(材質:SCM435/SUS304)

- TKJ MKJ-半圓頭十字螺絲(材質:鋼/不銹鋼)

- FBB SFBB-皿頭內六角螺絲(材質:SCM435/不銹鋼)

- TFBJ PFBJ-皿頭十字螺絲(材質:鋼/不銹鋼)

- SGR912.2-內六角螺絲(防脫落設計)(材質:SUS304)

- BBRSS BRSS-半圓頭十字螺絲(材質:鋼/不銹鋼)

- NSARA NSARAS-皿頭十字螺絲(材質:鋼/不銹鋼)

- BSARA BSARAS-低皿頭十字螺絲(材質:鋼/不銹鋼)

- TDJ TDJS-半圓頭十字螺絲(材質:鋼/不銹鋼)

- B722-外六角螺栓(材質:鋼)

- Y012-外六角螺栓(材質:鋼)

- B22-外六角螺栓(材質:鋼)(全牙)

- B23-外六角螺栓(材質:鋼)(全牙)

- B22-外六角螺栓(材質:鋼)(半牙)

- B23-外六角螺栓(材質:鋼)(半牙)

- Y111-外六角螺栓(材質:SCM435)

- Y306-外六角十字螺栓(材質:鋼)

- Y303-外六角十字螺栓(材質:不銹鋼)

- B730-內六角螺絲(材質:SCM435)(全牙)

- Y154-內六角螺絲(材質:鋼)(全牙)

- B30-內六角螺絲(材質:SCM435)(全牙)

- B44-內六角螺絲(材質:SUS304)(全牙)

- B730-內六角螺絲(材質:SCM435)(半牙)

- B62-內六角螺絲(材質:SCM435)

- Y154-內六角螺絲(材質:鋼)(半牙)

- B30-內六角螺絲(材質:SCM435)(半牙)

- B44-內六角螺絲(材質:SUS304)(半牙)

- B081-低頭內六角螺絲(材質:鋼)(全牙)

- B089-低頭內六角螺絲(材質:SUS304)(全牙)

- B774-半圓頭內六角螺絲(材質:SCM435)

- B773-皿頭內六角螺絲(材質:SCM435)

- B73-皿頭內六角螺絲(材質:SCM435)(全牙)

- B73-皿頭內六角螺絲(材質:SCM435)(半牙)

- B081-低頭內六角螺絲(材質:鋼)(半牙)

- Y311-超極低頭內六角螺絲(材質:SUS304)

- Y013-內六角螺絲(防鬆脫)(材質:SCM435)

- WGWA QCMT SCFT SSPT-內六角塑膠螺絲(材質:PC/RENY/PEEK/PPS)

- QCMP SCFPB SSPP PICB-低頭內六角塑膠螺絲(材質:RENY/PEEK/PPS/PI)

- QCMC SCFC SSPC-極低頭塑膠星型螺絲(材質:RENY/PEEK/PPS)

- RSCBP PEEKBT PPSBT-外六角塑膠螺栓(材質:PA/PEEK/PPS)

- SRAB SCFP SSPW-半圓頭十字塑膠螺絲(材質:RENY/PEEK/PPS)

- PEEKFH PPSFH-皿頭十字塑膠螺絲(材質:PEEK/PPS)

- CBP-內六角塑膠螺絲(材質:PC)

- PCPH-半圓頭十字塑膠螺絲(材質:PC)

- PCFH-皿頭十字塑膠螺絲(材質:PC)

- PCOH-圓皿頭十字塑膠螺絲(材質:PC)

- PCBT-外六角塑膠螺栓(材質:PC)

- PPSLH-星型塑膠螺絲(材質:PP)

- RENYBKPH-半圓頭十字塑膠螺絲(材質:RENY)

- RENYFH-皿頭十字塑膠螺絲(材質:RENY)

- RENYBT-外六角塑膠螺栓(材質:RENY)

- RENYTPH-半圓頭十字塑膠螺絲(材質:RENY)

- RENYMPH-超極低半圓頭十字塑膠螺絲(材質:RENY)

- RENYSMCH-超極低頭十字塑膠螺絲(材質:RENY)

- RENYLMCH-超極低頭十字塑膠螺絲(材質:RENY)

- PEEK-BT-外六角一字塑膠螺栓(材質:PEEK)

- PEEKLH-星型塑膠螺絲(材質:PEEK)

- PEEKMPH-超極低半圓頭十字塑膠螺絲(材質:PEEK)

- PEEKSMCH-超極低頭十字塑膠螺絲(材質:PEEK)

- PEEKLMCH-超極低頭十字塑膠螺絲(材質:PEEK)

- PEEKPH-半圓頭十字塑膠螺絲(材質:PEEK)

- PEEK-PH-超極低頭一字塑膠螺絲(材質:PEEK)

- PEEK-FH-皿頭一字塑膠螺絲(材質:PEEK)

- PEEKCB-內六角塑膠螺絲(材質:PEEK)

- PVDFPH-半圓頭十字塑膠螺絲(材質:PVDF)

- PVDFFH-皿頭十字塑膠螺絲(材質:PVDF)

- PVDFBT-外六角塑膠螺栓(材質:PVDF)

- PVDFCB-內六角塑膠螺絲(材質:PVDF)

- PFACB-內六角塑膠螺絲(材質:PFA)

- PFA-BT-外六角一字螺栓(材質:PFA)

- PFA-HH-一字塑膠螺絲(材質:PFA)

- PTFEBT-外六角塑膠螺栓(材質:PTFE)

- PVCBT-外六角塑膠螺栓(材質:PVC)

- PVCCB-內六角塑膠螺絲(材質:PVC)

- PPBT-外六角塑膠螺栓(材質:PP)

- FH-皿頭十字塑膠螺絲(材質:PEEK)

- PH-半圓頭十字塑膠螺絲(材質:PEEK)

- BPC-BTM-外六角塑膠螺栓(材質:PC)

- BPPS-BTM-外六角塑膠螺栓(材質:PPS)

- BRENY-BTM-外六角塑膠螺栓(材質:RENY)

- BPEEK-BTM-外六角塑膠螺栓(材質:PEEK)

- BPVC-BTM-外六角塑膠螺栓(材質:PVC)

- BPC-CBM-內六角塑膠螺絲(材質:PC)

- BPPS-CBM-內六角塑膠螺絲(材質:PPS)

- BRENY-BKCBM-內六角塑膠螺絲(材質:RENY)

- BPEEK-CBM-內六角塑膠螺絲(材質:PEEK)

- BPVC-CBM-內六角塑膠螺絲(材質:PVC)

- BRENY-BKLCM-低頭內六角塑膠螺絲(材質:RENY)

- BPEEK-LCM-低頭內六角塑膠螺絲(材質:PEEK)

- PEEKFH-皿頭十字塑膠螺絲(材質:PEEK)

- PEEKHB-外六角塑膠螺栓(材質:PEEK)

- PEEKPH-半圓頭十字塑膠螺絲(材質:PEEK)

- PEEKSCK-內六角塑膠螺絲(材質:PEEK)

- PEEKSC-內六角塑膠螺絲(材質:PEEK)

- PEEKSH-外六角一字螺栓(材質:PEEK)

- SCBPEKM-內六角塑膠螺絲(材質:PEEK)

- SCBFPEKM-內六角塑膠螺絲(材質:PEEK)

- SBTPEKM-外六角塑膠螺栓(材質:PEEK)

- SBTEPEKM-外六角一字螺栓(材質:PEEK)

- SBTPEKM-外六角塑膠螺栓(材質:PEEK)

- SCBFPEKM-內六角塑膠螺絲(材質:PEEK)

- SCBPEKM-內六角塑膠螺絲(材質:PEEK)

- SFHPEKM-皿頭十字塑膠螺絲(材質:PEEK)

- SPHPEKM-半圓頭十字塑膠螺絲(材質:PEEK)

- TR-模具彈簧(JIS規格(大壓縮量強力彈簧).壓縮量50%)

- TY-模具彈簧(JIS規格(大壓縮量強力彈簧).壓縮量50%)

- TF-模具彈簧(JIS規格(輕小荷重).壓縮量50%)

- TL TLR-模具彈簧(JIS規格(輕荷重).壓縮量40%)

- TM-模具彈簧(JIS規格(中等荷重).壓縮量32%)

- TH-模具彈簧(JIS規格(重荷重).壓縮量24%)

- TB-模具彈簧(JIS規格(極重荷重).壓縮量20%)

- TJL-模具彈簧(ISO規格(輕荷重).壓縮量40% )

- TJM-模具彈簧(ISO規格(中等荷重).壓縮量37.5% )

- TJH-模具彈簧(ISO規格(重荷重).壓縮量30% )

- TJB-模具彈簧(ISO規格(極重荷重).壓縮量25% )

- TU-模具彈簧(JIS規格(大壓縮量強力彈簧).壓縮量65%)

- LR-圓線彈簧(材質:SWOSC-V、壓縮量32%)

- LR MR-圓線彈簧(材質:SWOSC-V、壓縮量24%)

- LR-圓線彈簧(材質:SWOSC-V、壓縮量24%)(固定長度:1米)

- AY-圓線彈簧(材質:SWP、壓縮量75%)

- AR-圓線彈簧(材質:SWP、壓縮量60%)

- AF-圓線彈簧(材質:SWP、壓縮量45%)

- AL-圓線彈簧(材質:SWP、壓縮量40%)

- AT-圓線彈簧(材質:SWP、壓縮量40%)

- AM-圓線彈簧(材質:SWP、壓縮量35%)

- AH-圓線彈簧(材質:SWP、壓縮量30%)

- AB-圓線彈簧(材質:SWP、壓縮量25%)

- NAL NAM-圓線彈簧(材質:SWP、壓縮量32%/40%)

- OV-圓線彈簧(材質:SUS304、壓縮量70%)

- OY-圓線彈簧(材質:SUS304、壓縮量75%)

- OR-圓線彈簧(材質:SUS304、壓縮量60%)

- OF-圓線彈簧(材質:SUS304、壓縮量45%)

- OL-圓線彈簧(材質:SUS304、壓縮量40%)

- OT-圓線彈簧(材質:SUS304、壓縮量40%)

- OM-圓線彈簧(材質:SUS304、壓縮量35%)

- OH-圓線彈簧(材質:SUS304、壓縮量30%)

- OB-圓線彈簧(材質:SUS304、壓縮量25%)

- AG-氮氣彈簧(ISO標準(初始荷重250kgf))

- AG-氮氣彈簧(ISO標準(初始荷重500kgf))

- AG-氮氣彈簧(ISO標準(初始荷重750kgf))

- AG-氮氣彈簧(ISO標準(初始荷重1500kgf))

- AG-氮氣彈簧(ISO標準(初始荷重3000kgf))

- AG-氮氣彈簧(ISO標準(初始荷重5000kgf))

- AG-氮氣彈簧(ISO標準(初始荷重7500kgf))

- AG-氮氣彈簧(ISO標準(初始荷重10000kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重170kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重320kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重350kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重500kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重750kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重1000kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重1500kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重2400kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重4200kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重6600kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重9500kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重11800kgf))

- CW-氮氣彈簧(緊湊高度型(初始荷重20000kgf))

- CIMSR-薄墊片(材質:不銹鋼)

- LTPN-汽車模墊片(材質:SUS304)

- LBSNP D-DIP-A-汽車模墊片(材質:不銹鋼)

- BRB BRF-軸承墊片

- FRS.A FRS.S FRB.B FRC.C FRA.A-軸承墊片(尺寸客製)

- RS RB-層積型軸承墊片

- FRLS FRLB FRLA-層積型軸承墊片(尺寸客製)

- FFS.A FFS.S FFB.B FFC.C FFA.A-減速機墊片(尺寸客製)

- FKS.A FKS.S FKB.B FKC.C FKA.A-鍵槽墊片(尺寸客製)

- FCS.A FCS.S FCB.B FCC.C FCA.A-模具墊片(尺寸客製)

- D-DIP-C-汽車模墊片(材質:不銹鋼)

- PLTP-汽車模墊片(材質:SUS304)

- LBSFP-汽車模墊片(材質:SUS304)

- D-DIP-G-汽車模墊片(材質:不銹鋼)

- D-DIP-B-汽車模墊片(材質:SUS304)

- SMPP-汽車模墊片(材質:SUS304)

- MSSA MSSB-圓柱銷(材質:SUJ2)

- NP-圓柱銷(材質:SUJ2)

- WPW NPV-圓柱銷(材質:SUJ2)

- MSSE MSSF-圓柱銷(材質:SUS420)

- MSSC MSSD MSSG MSSH-圓柱銷(材質:不銹鋼)

- NPBG NPBGP-圓柱銷(材質:鋼、不銹鋼)(單邊螺紋)

- NPBN NPBNP NPB-圓柱銷(材質:鋼、不銹鋼)(單邊螺紋)

- NPBS NPBSE-圓柱銷(材質:鋼、不銹鋼)(單邊螺紋)

- NPKA NPKAN-圓柱銷(材質:SUJ2)

- TP-圓錐銷(材質:鋼、不銹鋼)(錐度:1/50)

- ITP-圓錐銷(材質:鋼、不銹鋼)(錐度:1/50)(單邊螺紋)

- OTP-圓錐銷(材質:鋼、不銹鋼)(錐度:1/50)

- ATP-圓錐銷(材質:鋼、不銹鋼)(錐度:1/48)(英制)

- 22630-定位銷(材質:鋼、不銹鋼)(球面)

- 22630-定位銷(材質:鋼)(平面、錐面)

- 22630.1~22630.4-定位銷(材質:鋼、不銹鋼)(平面)

- 22630.15~22630.18-定位銷(材質:鋼、不銹鋼)(平面)

- 22630-定位銷(材質:鋼)(錐面)

- 22630.35~22630.37-定位銷(材質:鋼、不銹鋼)(錐面)

- 22630.23~22630.26-定位銷(材質:鋼、不銹鋼)(錐面)

- 22630.52~22630.57-定位銷(材質:鋼、不銹鋼)(R型)

- 22630.5~22630.8-定位銷(材質:鋼、不銹鋼)(平面)

- 22630.11~22630.14-定位銷(材質:鋼、不銹鋼)(平面)

- 22630.19-定位銷(材質:鋼、不銹鋼)(平面)

- 22630.20~22630.22-定位銷(材質:鋼、不銹鋼)(平面)

- 22630.38~22630.41-定位銷(材質:鋼、不銹鋼)(錐面)

- 22630.42 22630.43 22630.58-定位銷(材質:鋼、不銹鋼)(錐面)

- 22630.27~22630.30-定位銷(材質:鋼、不銹鋼)(錐面)

- 22630.31~22630.34-定位銷(材質:鋼、不銹鋼)(錐面)

- 22630.44~22630.47-定位銷(材質:鋼、不銹鋼)(錐面)

- 22630.48~22630.51-定位銷(材質:鋼、不銹鋼)(錐面)

- SGR771.1-定位銷(材質:鋼)

- SGR179-定位銷(材質:鋼)(配件:SGR771.1專用襯套)

- SGR179.A SGR179.B SGR179.C-定位銷(材質:鋼)(配件:SGR771.1專用襯套)

- SGR172-定位銷(材質:鋼)(配件:SGR771.1專用襯套)

- SGR172.A SGR172.B SGR172.C-定位銷(材質:鋼、不銹鋼)(配件:SGR771.1專用襯套)

- 23110-定位銷(材質:鋼)(配件:襯套)

- GKS001 CRS.A SUSC.A-線性導桿(直型)

- GKS002 CRS.B SUSC.B-線性導桿(扣環槽型)

- GKS003 CRS.C SUSC.C-線性導桿(一端外螺紋同徑型)

- GKS004 CRS.D SUSC.D-線性導桿(兩端外螺紋同徑型)

- GKS005 CRS.E SUSC.E-線性導桿(一端內螺紋)

- GKS006 CRS.F SUSC.F-線性導桿(一端內螺紋帶板手槽型)

- GKS007 CRS.G SUSC.G-線性導桿(一端外螺紋)

- GKS008 CRS.H SUSC.H-線性導桿(一端外螺紋帶板手槽)

- GKS009 CRS.K SUSC.K-線性導桿(一端外螺紋帶退刀槽)

- GKS010 CRS.L SUSC.L-線性導桿(一端外螺紋帶退刀槽及板手槽)

- GKS011 CRS.M SUSC.M-線性導桿(兩端內螺紋)

- GKS012 CRS.N SUSC.N-線性導桿(兩端內螺紋帶板手槽)

- GKS013 CRS.P SUSC.P-線性導桿(兩端外螺紋)

- GKS014 CRS.Q SUSC.Q-線性導桿(兩端外螺紋帶板手槽)

- GKS015 CRS.R SUSC.R-線性導桿(兩端外螺紋帶退刀槽)

- GKS016 CRS.S SUSC.S-線性導桿(兩端外螺紋帶退刀槽及板手槽)

- GKS017 CRS.T SUSC.T-線性導桿(內外螺紋)

- GKS018 CRS.U SUSC.U-線性導桿(內外螺紋帶板手槽)

- GKS019 CRS.V SUSC.V-線性導桿(內外螺紋帶退刀槽)

- GKS020 CRS.W SUSC.W-線性導桿(內外螺紋帶退刀槽及板手槽)

- GKS021 CRS.X SUSC.X-線性導桿(一台階內螺紋)

- GKS022 CRS.Y SUSC.Y-線性導桿(一台階內螺紋帶板手槽)

- GKS023 CRS.Z SUSC.Z-線性導桿(一台階兩內螺紋)

- GKS024 CRS.AB SUSC.AB-線性導桿(一台階兩內螺紋帶板手槽)

- GKS025 CRS.AC SUSC.AC-線性導桿(一台階外螺紋)

- GKS026 CRS.AD SUSC.AD-線性導桿(一台階內外螺紋)

- GKS027 CRS.AE SUSC.AE-線性導桿(兩台階)

- GKS028 CRS.AF SUSC.AF-線性導桿(兩台階內螺紋)

- GKS029 CRS.AG SUSC.AG-線性導桿(一端內螺紋帶錐度)

- GKS030 CRS.AH SUSC.AH-線性導桿(一端外螺紋帶錐度)

- GKS031 CRS.AK SUSC.AK-線性導桿(一台階內螺紋帶錐度)

- GKT003-導桿架(標準-安裝孔鑽孔型)

- GKT004-導桿架(導引部長型-安裝孔鑽孔型)

- GKT005-導桿架(標準-安裝孔攻牙型)

- GKT006-導桿架(標準-壓入型)

- GKT007-導桿架(標準-附定位孔型)

- GKT008-導桿架(壁厚型-標準-安裝孔鑽孔型)

- GKT009-導桿架(壁厚型-導引部加長-安裝孔鑽孔型)

- GKT010-導桿架(壁厚型-壓入型)

- GKT011-導桿架(壁厚型-附定位孔型)

- GKT018-導桿架(壁厚型-附鍵槽型)

- GKT012-導桿架(開縫型-標準-安裝孔鑽孔型)

- GKT013-導桿架(開縫型-導引部加長-安裝孔鑽孔型)

- GKT014-導桿架(開縫型-壓入型)

- GKT015-導桿架(開縫型-附定位孔型)

- GKT019-導桿架(開縫型-分離型)

- GKT016-導桿架(圓型-精巧型)

- GKT017-導桿架(圓型-導引部加長-精巧型)

- BTM-MXL-時規皮帶(MXL)

- BOM-MXL-時規皮帶(MXL)

- BTM-XL-時規皮帶(XL)

- BOM-XL-時規皮帶(XL)

- BTM-L-時規皮帶(L)

- BOM-L-時規皮帶(L)

- BTM-H-時規皮帶(H)

- GBTM-S2M/S3M-時規皮帶(S2M/S3M)

- GBOM-S2M-時規皮帶(S2M)

- GBOM-S3M-時規皮帶(S3M)

- GBTM-S5M-時規皮帶(S5M)

- GBTM-S8M/S14M-時規皮帶(S8M/S14M)

- GBTM-P2M-時規皮帶(P2M)

- GBTM-P3M-時規皮帶(P3M)

- GBTM-P5M/P8M-時規皮帶(P5M/P8M)

- BBTO-T5-時規皮帶(T5)

- BBTO-T10-時規皮帶(T10)

- HTM-2GT-時規皮帶(2GT)

- HTM-3GT-時規皮帶(3GT)

- HTM-5GT-時規皮帶(5GT)

- HTM-8YU-時規皮帶(8YU)

- WBS、TBS、FBS、MBS、NBS、NBST、NBSS-時規皮帶輪(MXL)

- WBS、TBS、FBS、MBS、NBS、NBST、NBSS-時規皮帶輪(XL)

- WBSW、WBST、WBSF、WBSM、WBSB、WBS、WBSS-時規皮帶輪(L)

- WBSW、WBST、WBSF、WBSM、WBSB、WBS、WBSS-時規皮帶輪(H)

- GBSW、GBST、GBSF、GBSM、GBSB、GBSN、GBSS-時規皮帶輪(S2M)

- GBSW、GBST、GBSF、GBSM、GBSB、GBSN、GBSS-時規皮帶輪(S3M)

- GBSW、GBST、GBSF、GBSM、GBSB、GBSN、GBSS-時規皮帶輪(S5M)

- GBSW、GBST、GBSF、GBSM、GBSB、GBSN、GBSS-時規皮帶輪(S8M)

- GBSBMK、GBSNMK-時規皮帶輪(S14M)

- SBSW-時規皮帶輪(P2M)

- SBSW、SBSN、SBSS-時規皮帶輪(P3M)

- SBSW、SBST、SBSF、SBSM、SBSN、SBSS-時規皮帶輪(P5M)

- SBSW、SBSF、SBSM、SBSN、SBSS-時規皮帶輪(P8M)

- BBSW、BBST、BBSF、BBSM、BBSB、BBSN、BBSS-時規皮帶輪(T5)

- BBSW、BBST、BBSF、BBSM、BBSB、BBSN、BBSS-時規皮帶輪(T10)

- BBSW、BBST、BBSF、BBSM-時規皮帶輪(AT5)

- BBSW、BBST、BBSF、BBSM-時規皮帶輪(AT10)

- HSW-時規皮帶輪(1.5GT)

- HSW-時規皮帶輪(2GT)

- HSW、HSB、HSN-時規皮帶輪(3GT)

- HSW、HSB、HSN-時規皮帶輪(5GT)

- HSW、HSB、HSN-時規皮帶輪(8YU)

- SGR251.2-定位珠(材質:鋼)(附感測器)

- SGR615.7-定位珠(材質:鋼)(附感測器)

- 22030-定位珠(材質:鋼/SUS303)(內六角)

- 22031-定位珠(材質:鋼/SUS303)(內六角)

- BP SBP-定位珠(材質:鋼/SUS304)(內六角)

- 22030-定位珠(材質:鋼/SUS303)(內六角)

- 22050-定位珠(材質:鋼/SUS303)(一字型)

- 22050-定位珠(材質:SUS316)(一字型)

- MBP SMBP-定位珠(材質:鋼/SUS303)(一字型)

- 22050-定位珠(材質:鋼/SUS303)(一字型)

- 22051-定位珠(材質:鋼/SUS303)(一字型)

- 22040-定位珠(材質:POM)(一字型)

- 2B050-定位珠(材質:鋼/SUS303)(一字型)(英制)

- 22080-定位珠(材質:SUS303)(嵌入型)

- 22080-定位珠(材質:SUS305)(嵌入型)

- 22090-定位珠(材質:黃銅)(嵌入型)(雙向)

- 22080-定位珠(材質:POM)(嵌入型)

- 2B080-定位珠(材質:POM)(嵌入型)(英制)

- 22080-定位珠(材質:SUS303/黃銅/POM)(嵌入型)

- SGR614.1-定位珠配件(材質:鋅合金)(支架)

- SGR250-定位珠配件(材質:燒結鋼)(V型座)

- SGR249.1-定位珠配件(材質:鋼)(固定座)

- TBT-定位珠配件(材質:SK4)(固定座)

- 22075-定位珠(材質:鋼/SUS303/POM)(軸環型)

- 22051-定位珠(材質:SUS)(一字型)

- SPS-L SPS-H-定位柱(材質:鋼)(內六角)

- 25010-定位柱(材質:SUS303)(內建感測器接頭)

- 25020-定位柱(材質:鋼)(可外接感測器)

- 2B020-定位柱(材質:鋼)(一字型)(英制)

- 2B020-定位柱(材質:SUS303)(一字型)(英制)

- 22050-定位柱(材質:鋼/SUS303)(一字型)

- 22030-定位柱(材質:鋼/SUS303)(內六角)

- 2B030-定位柱(材質:鋼)(內六角)(英制)

- 2B030-定位柱(材質:SUS303)(內六角)(英制)

- 22060-定位柱(材質:鋼/SUS303)(內六角)

- 22060-定位柱(材質:鋼/SUS303)(內六角)(防塵)

- MBHC MBHF-定位柱(材質:S45C)

- MBHG MBHS-定位柱(材質:S45C)

- SJLF SJLTP SJHTP-定位柱(材質:S45C)(平面)

- NSP-L-定位柱(材質:S45C)(經濟型)

- NSJS-N NSJL-N NSJH-N-定位柱(材質:S45C)(經濟型)

- SJS-N SJL-N SJH-N SJX-N-定位柱(材質:S45C)(經濟型)

- NSJS NSJL NSJH NSJX-定位柱(材質:S45C)(經濟型)

- SJS SJL SJH SJX-定位柱(材質:S45C)(經濟型)

- SP-H-定位柱(材質:SCM435)

- SP-L-定位柱(材質:SCM435)

- 22070-定位柱(材質:鋼/SUS303)

- 22070-定位柱(材質:鋼/SUS303)(嵌入型)

- 22080-定位柱(材質:SUS305)(嵌入型)

- SGR513-定位柱(材質:鋼)

- 22100-定位柱(材質:鋼/SUS304)(簡易型)

- SGR8170-分割定位柱(材質:SUS316)(衛生型)

- SGR8170-分割定位柱(材質:SUS316)(衛生型)

- SGR817.6-分割定位柱(材質:SUS303)(附感測器)

- SGR417-分割定位柱(材質:鋅合金)(法蘭型)

- SGR722.2-分割定位柱(材質:鋼/SUS316)(法蘭型)

- SGR722.3-分割定位柱(材質:鋼)(法蘭型)

- 22120-分割定位柱(材質:鋼)(法蘭型)

- 22120-分割定位柱(材質:鋼)(焊接型)

- SGR612.3-分割定位柱(材質:鋼/SUS304)(焊接型)

- SGR722.1-分割定位柱(材質:鋼)(焊接型)

- 22120-分割定位柱(材質:鋅合金)(法蘭型)

- 22120-分割定位柱(材質:鋼)(有旋鈕)

- SGR514-分割定位柱(材質:鋼)(按壓型)

- PMT.100-分割定位柱(材質:PA)(有旋鈕)

- PMT.101-分割定位柱(材質:PA)(有旋鈕)

- 22110-分割定位柱(材質:鋼/SUS303)(有旋鈕/無旋鈕)

- 22110-分割定位柱(材質:鋼)(有旋鈕)

- SGR817-分割定位柱(材質:鋼/SUS303)(有旋鈕)

- SGR817-分割定位柱(材質:鋼/SUS303)(有旋鈕)

- SGR818-分割定位柱(材質:SUS316)(有旋鈕)

- SGR818-分割定位柱(材質:SUS316)(有旋鈕)

- 22120-分割定位柱(材質:SUS303)(有旋鈕)

- 22120-分割定位柱(材質:SUS303)(有旋鈕)

- 22120-分割定位柱(材質:SUS303)(有旋鈕)

- 22120-分割定位柱(材質:鋼/SUS303)(有旋鈕)

- 22120-分割定位柱(材質:鋼/SUS303)(有旋鈕)

- 22120-分割定位柱(材質:鋼/SUS303)(有旋鈕)

- 22120-分割定位柱(材質:鋼/SUS303)(有旋鈕)

- 22120-分割定位柱(材質:鋼/SUS303)(有旋鈕/無旋鈕)

- 22120-分割定位柱(材質:鋼/SUS303)(無旋鈕)

- 22120-分割定位柱(材質:鋼/SUS303)

- 22120-分割定位柱(材質:鋼/SUS303)

- 22130-分割定位柱(材質:鋼)(精密型)

- 22130-分割定位柱(材質:鋼)(精密型)

- SGR7336.7-分割定位柱(材質:鋼)(有旋鈕)

- 1087-分割定位柱(材質:鋼)(有旋鈕)

- SGR816.1-分割定位柱(材質:鋼)(銷子內藏型)

- SGR816-分割定位柱(材質:鋼)(銷子外伸型)

- 22120-分割定位柱(材質:鋼/SUS303)(有旋鈕)(短型)

- SGR822.1-分割定位柱(材質:鋼/SUS303)(有旋鈕)(短型)

- SGR7336.8-分割定位柱(材質:鋼)(有旋鈕)(短型)

- 22110-分割定位柱(材質:鋼/SUS303)(有旋鈕)(短型)

- SGR822-分割定位柱(材質:鋼/SUS303)(有旋鈕)(短型)

- SGR612.8-分割定位柱(材質:鋅合金)(短型)

- SGR609.5-分割定位柱(材質:SUS303)(配件:調整環)

- SGR712.1-分割定位柱(材質:鋼)(銷子內藏型)

- SGR712-分割定位柱(材質:鋼)(銷子外伸型)

- SGR412.1-分割定位柱(材質:鋅合金)(配件:支撐座)

- SGR412.2 SGR412.4-分割定位柱(材質:鋼/SUS431)(配件:襯套)

- SGR412.3 SGR412.5-分割定位柱(材質:鋼/SUS431)(配件:斜面襯套)

- SGR414-分割定位柱(材質:鋼)

- SGR817.3-分割定位柱(材質:鋼)(有旋鈕)

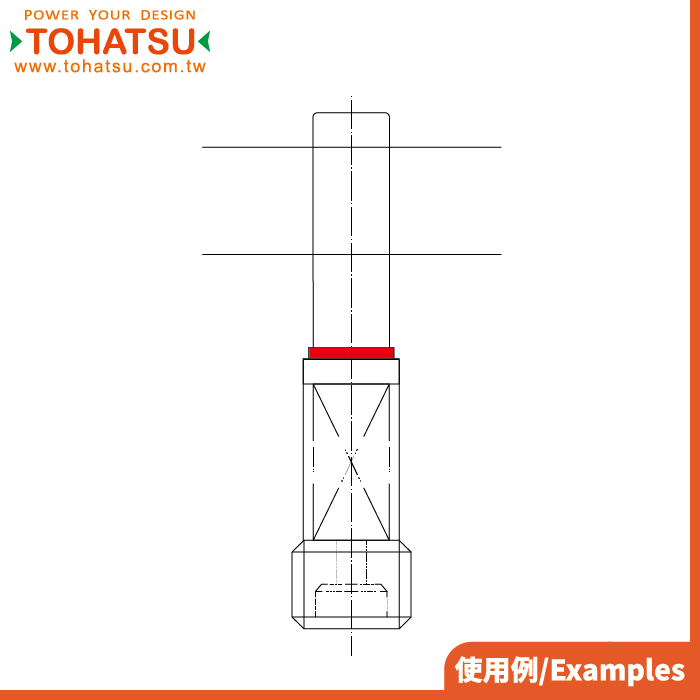

平墊片/華司

模具墊片(材質:SK5)

MSRBB LRBB

墊圈又稱華司,是通常用於墊在連接件與螺母之間的零件。

主要用途是作為間隔物用來保護被連接件的表面不受螺母擦傷,分散螺母對被連接件的壓力,及減少振動帶來的脫離。

常用材質:鋼、不銹鋼、銅、鋁、鐵、塑膠、鈦

主要應用行業:工業、模具、設備...等

墊圈可分為三種類型

1.平墊圈

作用:防止連接件表面損傷,增大接觸面積分散壓力。

2.彈簧墊圈

作用:用於柔性地防止鬆動及振動。

3.防鬆墊圈

作用:防止連接件鬆動及防止螺絲的轉動。

墊片是兩個物體之間的機械密封,通常用以防止兩個物體之間受到壓力、腐蝕、和管路泄漏。

由於機械加工表面不可能完美,使用墊片即可填補不規則性。

主要用途:管法蘭,閥,泵,壓力容器...等一些專業設備的密封

主要應用行業為石化,煉化,電力,冶金,製造等行業