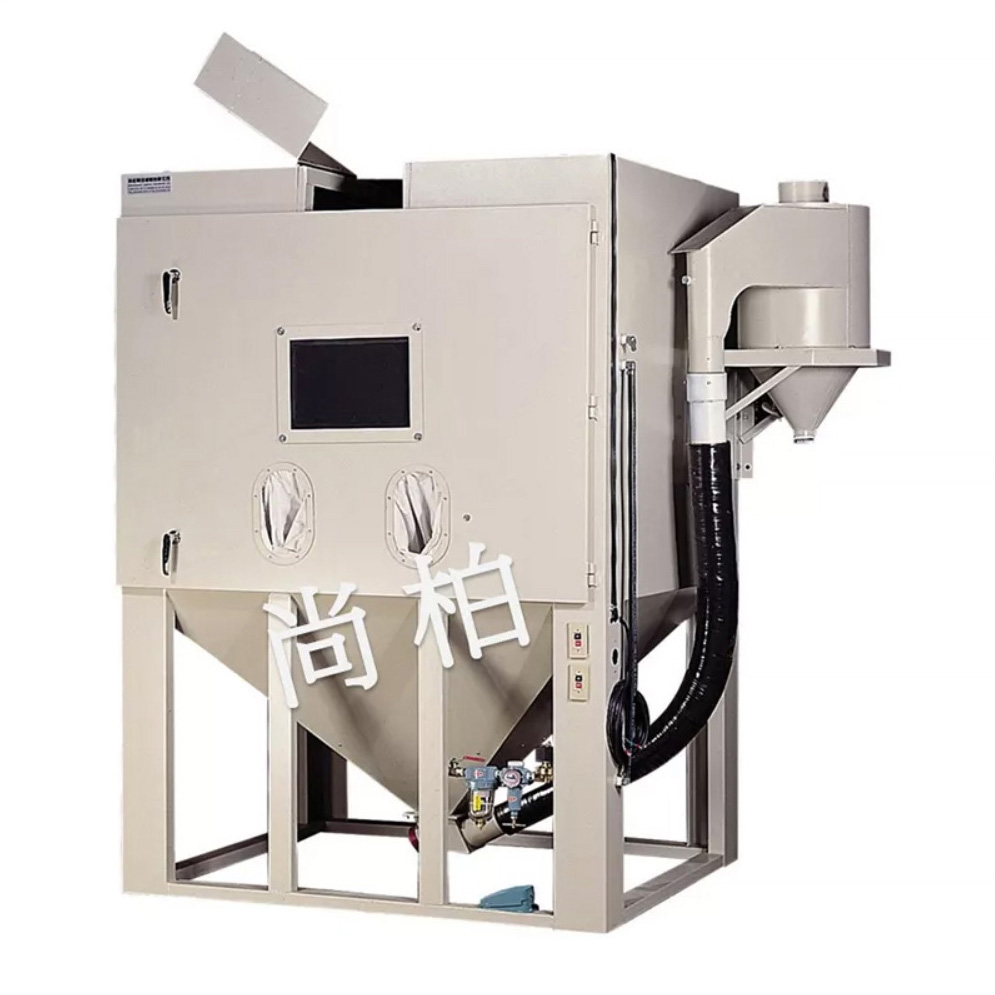

Products

Equipped with a large-sized blasting device the Shang Po Bulk Sand Blasting Cabinet is suitable for patterning of large-sized molds or blasting operation of large-sized workpieces (bicycle's frames, for example). The processing speeds of the bulk sand blasting cabinets are twice the ordinary siphoning blasting cabinets.

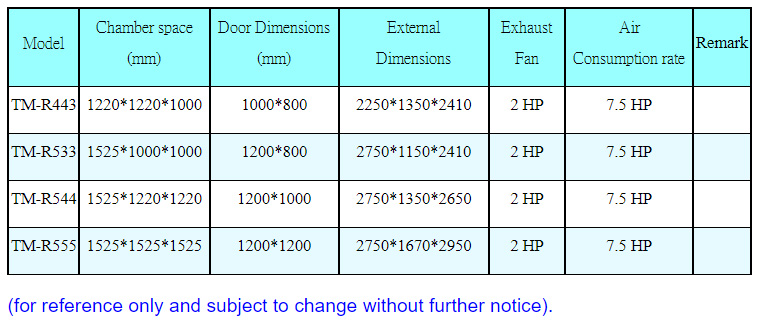

Model : TM-R443 / TM-R555

1. Automatic sand recycle for use with pedal controlling. Equipped with Shang Po's super-durable boron carbon blasting nozzles with pressures at 0.5-7kgs.

2. Max. sand capacity: 25KG aluminum oxide or glass beads, available for several times of recycles for a long period of time.

3. The biggest sand material in diameter used by the machine: aluminum oxide 24#, steel shots 0.6mm below.

4. The smallest sand material in diameter used is above 320#. (custom-made with the smallest material being 800#).

5. Blasting injection-control system: adopts a DPC brand's 1/2 pressure-adjustment filter and can carry out a perfect injection-control by accompanying an electromagnetic valve(s). Can meet the requirements of effective filtering, pressure adjustment and stable injection.

6. Filtering of sand material: adopts double, large-dimensional filtering net for filtering. Not only makes sure the quality of injected sand material but thereby reduces the rate of blocking the blasting device, achieving a smooth blasting process.

7. With a powerful and effective twin air-convection hole design, able to proceed air-exchange rapidly and effectively at blasting. Not only makes the indoor visibility more clear but not causes powder pollution, an advantage for health.

8. Patented cyclone separators can separate material 150#-320# in micro-adjustment. Under the sand-saving requirement of the user, it can also be both strong and stable for injection flow. Its major function is to effectively separate sand dust. Not only the stability of the workpiece's surface processed is enhanced and processing time is saved but more than 30% sand material is saved compared to other types. Consequently, the collecting cabin of the dust-collector can be found only useless powder but not usable sand material.

9. Dust-collector: uses 2-HP dust-collection motor. Both inlet and outlet adopt a large diameter 6" for a large flow design. Air exhaust is 16m3/min to make sure speed and flow both can meet the requirements for the operation of the dust-collector.

10. Filtering-cloth pipe for dust-collection: with a total of 25 filtering-cloth pipes with an overall filtering dimension of 5.6m2. The filtering cloth is made from 1000# twill.

11. Large-sized blasting devices can be custom-made for sizes and optional for manual or automatic rotational disc and conveyor tracks.

12. [Options] With a twin-opening and open-top design molds can be lifted down in the blasting chamber for hanging blasting, convenient and safe. Excellent sealing for sand material without polluting the environment. A benefit for heavyweight molds and large-sized workpieces in blasting.

13. Equipped with an air-cleaning device, not only for cleaning the workpiece but for preventing the loss of sand material being brought out of the sand cabin.

14. Provided with an anti-dust and waterproof fluorescent lamp set, for the prevention of sand material breaking the bulb endangering the safety of the operator.